Automatic Blow Molding Machine Company Innovations for Custom Bottle Design

Automatic Blow Molding Machine Company Innovations for Custom Bottle Design

Leshan, a renowned blow molding machine manufacturer, is at the forefront of automatic blow molding innovations for custom bottle design. Leveraging advanced automation, precision controls, and AI-driven quality assurance, Leshan empowers brands across industries to achieve unique, functional, and visually striking packaging. The company’s machines support rapid mold changeovers, accommodate a wide range of plastic materials—including recycled and bio-based resins—and ensure energy-efficient, high-speed production. Key innovations such as digital design integration, real-time IoT monitoring, and modular machine architectures enable seamless transitions from prototype to mass production. Leshan’s customer-centric approach, global reach, and commitment to sustainability position it as a leader in meeting the evolving demands of modern packaging, making it a preferred partner for businesses seeking to differentiate through cutting-edge bottle design and manufacturing technology.

In the dynamic world of plastic container manufacturing, custom bottle design is increasingly at the forefront of market differentiation. Leshan, a leading blow molding machine manufacturer, stands out in this sector by continually pioneering automatic blow molding machine innovations. As consumer demand for unique packaging solutions rises, Leshan leverages its technological expertise to offer tailored solutions for a wide array of industries, including food and beverage, cosmetics, pharmaceuticals, and household chemicals. This article explores the groundbreaking advancements Leshan brings to automatic blow molding, their impact on custom bottle design, and how these innovations shape the industry landscape.

Understanding Automatic Blow Molding Technology

Automatic blow molding machines represent a significant evolution from manual and semi-automatic systems. With precise control systems, rapid cycle times, and integrated quality assurance protocols, these machines can produce complex bottle shapes with remarkable consistency and efficiency. Leshan’s automatic blow molding machines are engineered for versatility, supporting extrusion blow molding, injection blow molding, and stretch blow molding technologies. This multifaceted approach enables manufacturers to address a wide spectrum of design requirements, material preferences, and production volumes.

Leshan: A Pioneer in Blow Molding Machine Manufacturing

Leshan’s journey as a blow molding machine manufacturer is marked by an unwavering commitment to innovation and quality. The company’s research and development teams continually seek out new materials, machine architectures, and automation strategies, resulting in proprietary solutions that enhance the speed, precision, and flexibility of bottle production. By integrating Industry 4.0 concepts such as IoT-enabled monitoring and smart diagnostics, Leshan’s machines provide real-time feedback, ensuring optimal performance, reduced downtime, and minimal waste. This not only maximizes productivity but also enables customers to rapidly prototype and scale new bottle designs.

Key Innovations in Leshan’s Automatic Blow Molding Machines

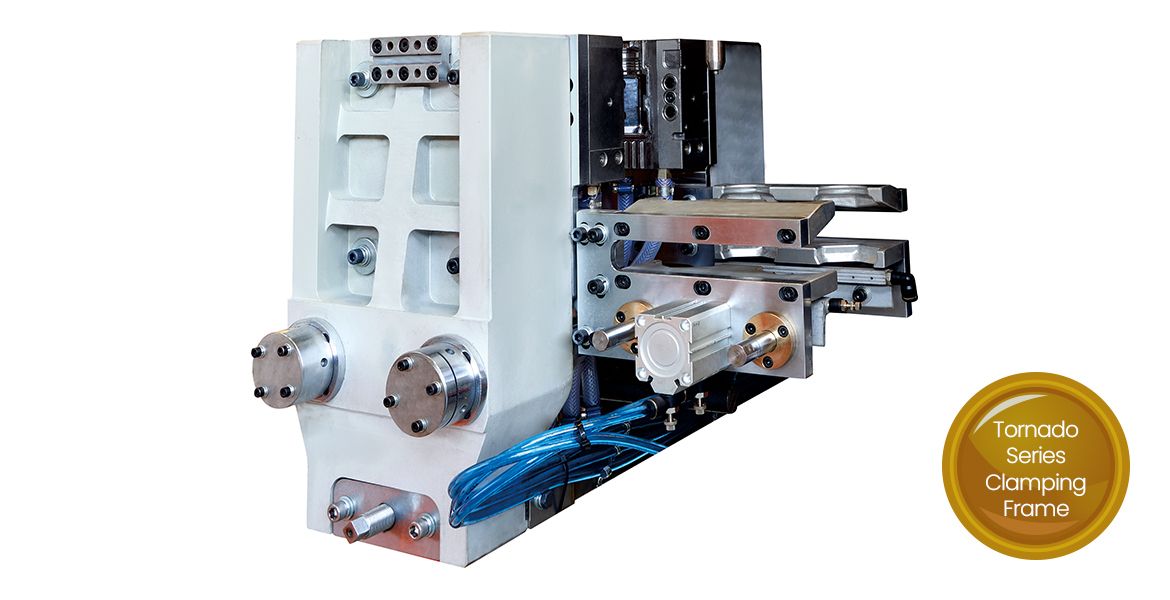

- Advanced Mold Design Integration: Leshan’s machines support rapid mold changeovers and modular mold components, allowing for seamless customization of bottle shapes, sizes, and surface textures.

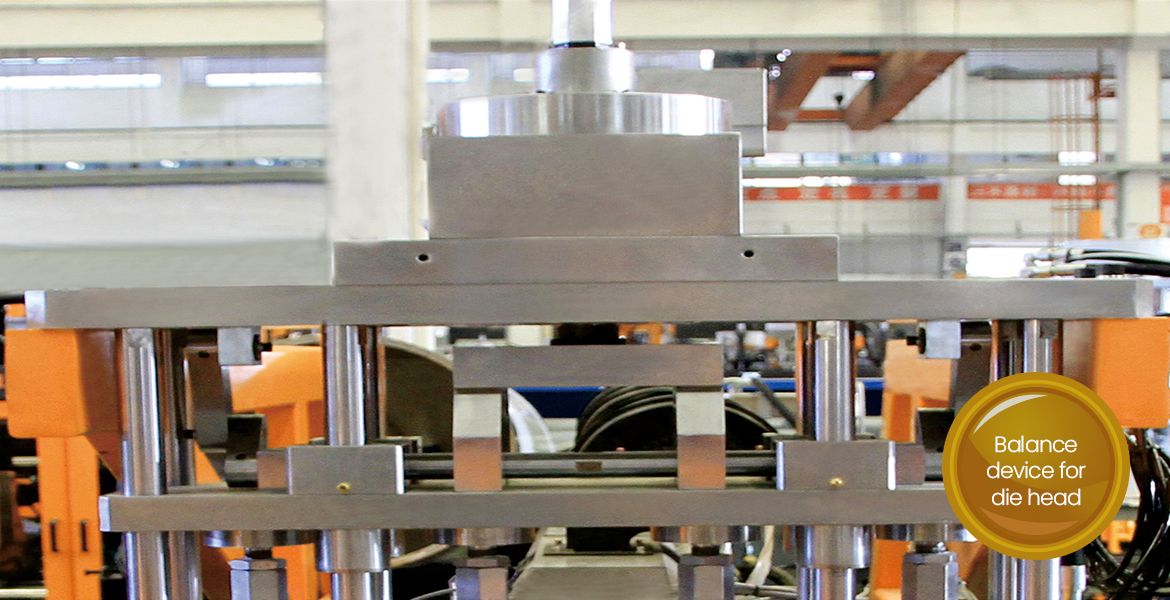

- Precision Process Control: Proprietary control algorithms ensure consistent wall thickness, weight distribution, and dimensional accuracy, even for intricate bottle geometries.

- Material Versatility: Leshan’s platforms handle a wide range of thermoplastics including PET, HDPE, LDPE, and PP, as well as recycled and bio-based polymers for sustainability.

- Smart Automation: Machine vision systems and AI-driven quality checks detect defects instantly, enabling continuous improvement and reducing waste.

- Energy Efficiency: State-of-the-art servo motors and energy recovery systems lower operational costs while supporting high-speed production cycles.

The Custom Bottle Design Revolution

Customization in bottle design is no longer limited to basic branding elements. Modern consumers and brands demand packaging with ergonomic forms, functional closures, tactile surfaces, and unique visual identities. Leshan’s automatic blow molding machines empower brands to experiment with unconventional silhouettes, embossed patterns, and integrated features like handles and measuring marks. The ability to rapidly iterate and prototype new concepts translates into shorter time-to-market for innovative products, giving Leshan’s customers a decisive competitive edge.

Design Flexibility: From Concept to Mass Production

One of Leshan’s key differentiators is its approach to design flexibility. The company collaborates closely with clients, utilizing advanced computer-aided design (CAD) and simulation tools to visualize bottle concepts before physical molds are created. Once approved, the automatic machines translate digital designs into high-precision molds, ensuring that every detail of the intended design is faithfully reproduced. With integrated hot-runner systems and post-molding automation, the transition from prototype to mass production is seamless.

Case Studies: Real-World Applications

| Industry | Custom Design Feature | Leshan’s Solution |

|---|---|---|

| Cosmetics | Unique ergonomic bottle with embossed logo | Multi-cavity mold with 3D surface texturing and rapid changeover |

| Beverage | Lightweight bottle with integrated handle | Precision wall thickness controls, handle-forming module |

| Pharmaceutical | Child-resistant closure, measuring scale | Automated assembly integration, high-precision molds |

| Home Care | Wide-mouth bottle, custom closure threads | Flexible mold design, servo-driven neck forming |

Enhancing Sustainability through Innovation

As environmental concerns become ever more pressing, Leshan’s innovations extend beyond performance and aesthetics. The company’s machines are optimized for energy-efficient operation, minimizing carbon footprints. More importantly, Leshan’s support for recycled and bio-based plastic resins enables circular economy strategies. Brands can now offer bottles with high recycled content or even compostable materials, responding to consumer preferences and regulatory pressures without sacrificing design customizability or production efficiency.

Industry 4.0 and Digital Transformation

Leshan’s adoption of digital technologies transforms the way bottle manufacturing is managed. IoT sensors and real-time analytics allow operators to track production metrics, predict maintenance needs, and swiftly resolve issues. Remote monitoring and cloud-based data sharing facilitate collaboration between design teams, operators, and maintenance staff, regardless of geographic location. This connectivity not only drives operational excellence but also fosters continuous learning and process refinement.

Customer-Centric Approach: Partnerships for Success

Leshan recognizes that each customer’s requirements are unique. From initial consultation through to after-sales support, Leshan’s engineers and designers work hand-in-hand with clients to understand their vision, technical constraints, and market goals. This collaborative approach ensures that every automatic blow molding system delivered is tailored for maximum impact, reliability, and ease of operation. Comprehensive training, remote diagnostics, and spare parts support further reinforce long-term success.

Global Reach, Local Expertise

While Leshan operates on a global scale, the company maintains a network of regional service centers and technical experts. This local presence ensures rapid response times, culturally relevant support, and a deep understanding of evolving market trends. Leshan’s commitment to knowledge transfer and skill development empowers customers to maximize the value of their investment in blow molding technology.

Future Outlook: Continuous Innovation

The future of custom bottle design is marked by higher complexity, increased automation, and greater sustainability demands. Leshan’s ongoing investment in research, talent development, and technological integration positions the company at the leading edge of this transformation. With a clear vision and a proven track record, Leshan continues to redefine what’s possible in automatic blow molding machine manufacturing, delivering solutions that inspire creativity and operational excellence.