Automatic Blow Molding Machine Energy-Saving Solutions for Modern Factories

Automatic Blow Molding Machine Energy-Saving Solutions for Modern Factories

Leshan, a renowned blow molding machine manufacturer, offers advanced energy-saving solutions tailored for modern factories. Their automatic blow molding machines incorporate state-of-the-art technologies such as high-efficiency servo motors, intelligent heating systems, efficient cooling mechanisms, variable frequency drives, and air recovery systems. These features collectively reduce energy consumption, lower operational costs, and enhance production quality.

Leshan’s holistic approach to energy efficiency includes machine integration with factory energy management systems, comprehensive operator training, and ongoing technical support. Comparative analyses show that Leshan’s solutions outperform traditional machines in terms of energy usage, automation, and sustainability. Real-world case studies from food packaging, automotive, and cosmetic industries demonstrate substantial energy savings—ranging from 20% to 30%—and improvements in productivity and uptime.

Best practices for maximizing these benefits include regular data analysis, maintaining optimal machine settings, investing in continuous operator training, and embracing automation. Leshan’s ongoing R&D ensures that its blow molding machines remain at the cutting edge of energy efficiency, making them a preferred choice for environmentally responsible and cost-conscious manufacturers worldwide.

As the demand for sustainable manufacturing continues to rise, energy efficiency has taken center stage within the plastics industry. Leshan, a leading blow molding machine manufacturer, is at the forefront of innovating energy-saving solutions for modern factories. In this article, we delve into the strategies, technologies, and best practices that enable Leshan’s automatic blow molding machines to deliver superior energy efficiency without compromising on performance or product quality.

Understanding Blow Molding Machines

Blow molding is a critical process in producing hollow plastic products such as bottles, containers, and automotive components. The automatic blow molding machine, as manufactured by Leshan, streamlines this process with high-speed, high-precision, and high-volume capabilities. However, traditional blow molding operations can be energy-intensive due to the need for heating, cooling, air compression, and mechanical movements.

Modern factories are increasingly seeking out solutions that lower operational costs while reducing their environmental impact. The focus has thus shifted towards adopting advanced blow molding machines that are designed with energy-saving features at their core.

Key Energy-Saving Technologies in Leshan Blow Molding Machines

1. High-Efficiency Servo Motor Systems

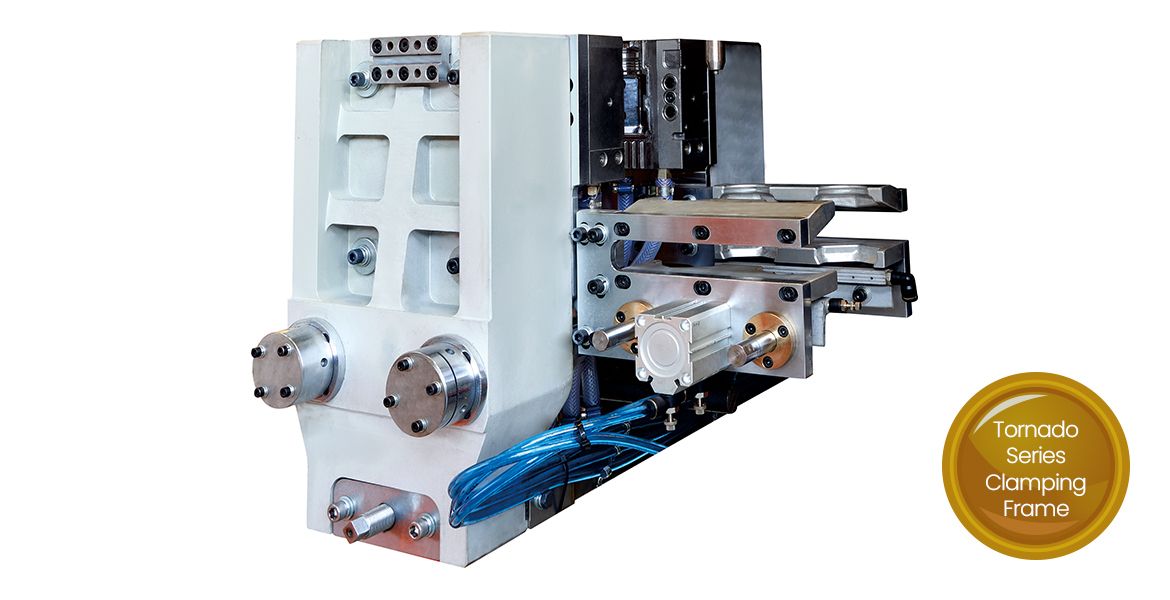

Leshan’s latest automatic blow molding machines integrate high-efficiency servo motors, replacing conventional hydraulic systems. Servo motors provide precise control over movement and significantly reduce energy consumption by delivering power only when needed. This not only cuts energy bills but also enhances the accuracy and consistency of the finished products.

2. Intelligent Heating Systems

Heating the plastic parison is one of the most energy-consuming steps in blow molding. Leshan employs advanced heating technologies such as ceramic infrared heaters and segmented temperature control. These systems ensure optimal energy use by focusing heat only on required areas and quickly adjusting to temperature changes, minimizing energy waste.

3. Efficient Cooling Mechanisms

Cooled molds are essential for rapid production cycles and product quality. Leshan utilizes innovative cooling channel designs and smart coolant flow control to maintain ideal mold temperatures with lower energy input. Additionally, heat exchangers recycle thermal energy where possible, further reducing overall consumption.

4. Variable Frequency Drives (VFDs)

VFDs adjust the speed of motors in real time, based on load requirements. Leshan outfits its blow molding machines with VFDs to optimize the energy used during each production stage, from parison extrusion to mold clamping and ejection. This dynamic approach eliminates unnecessary energy expenditure during idle or low-load periods.

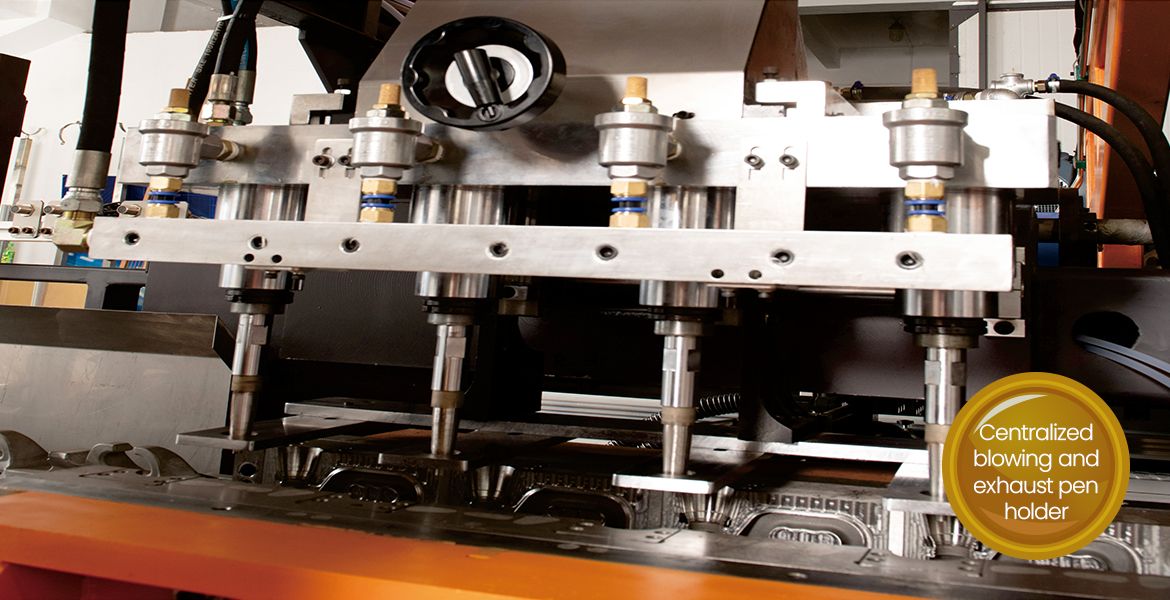

5. Air Recovery and Optimization Systems

Compressed air is vital for blow molding, but traditional systems often result in significant air and energy loss. Leshan’s machines are equipped with air recovery units that capture and recycle unused air, effectively lowering compressor workload and reducing energy consumption. Additionally, smart monitoring systems detect leaks early and facilitate predictive maintenance.

Implementing Energy-Saving Solutions in Modern Factories

Deploying Leshan’s automatic blow molding machines in a factory environment requires a holistic approach to maximize the benefits of energy-saving features. Factory managers and engineers should consider the following steps:

- Energy Auditing: Assess current energy use and identify key areas for improvement.

- Machine Integration: Seamlessly connect blow molding machines to factory-wide energy management systems for real-time monitoring and optimization.

- Operator Training: Educate staff on best practices for operating energy-efficient machinery and monitoring performance metrics.

- Preventive Maintenance: Schedule regular inspections and maintenance to keep all systems running at peak efficiency.

- Retrofitting Existing Equipment: Upgrade older machines with energy-saving modules, such as servo drives or advanced heating elements, where feasible.

Leshan supports its customers with turnkey installation services and ongoing technical guidance, ensuring that factories unlock the full potential of their energy-saving investments.

Comparative Analysis of Energy-Saving Features

| Feature | Traditional Machines | Leshan Automatic Blow Molding Machines |

|---|---|---|

| Motor Technology | Standard Hydraulic | High-Efficiency Servo Motors |

| Heating System | Conventional Resistance | Intelligent Ceramic/Infrared |

| Cooling | Basic Water Flow | Smart Cooling Control & Heat Recovery |

| Compressed Air | High Loss, No Recovery | Air Recovery & Leak Detection |

| Control System | Manual/Basic PLC | Advanced Automation & Monitoring |

This comparative overview underscores how Leshan’s innovations drive significant energy savings and process optimizations, setting a new industry benchmark for sustainable operations.

Case Studies: Leshan Energy-Saving Solutions in Action

Food & Beverage Packaging Plant

A leading beverage producer implemented Leshan automatic blow molding machines and reported a 30% reduction in energy consumption. By leveraging servo drives and air recovery systems, the plant also achieved higher throughput and lower scrap rates, enhancing overall profitability.

Automotive Component Manufacturer

An automotive supplier upgraded its production line with Leshan’s intelligent heating and cooling systems. The result was a 25% decrease in energy costs and improved dimensional accuracy in critical components. Integrated VFDs further reduced wear and maintenance needs, boosting uptime.

Cosmetic Packaging Facility

Leshan’s solutions enabled a cosmetic packaging factory to halve its compressed air usage and cut its energy bills by 20%. Real-time data analytics allowed for quick response to inefficiencies, and predictive maintenance minimized unplanned downtime.

Best Practices for Maximizing Energy Savings

- Regularly review and analyze energy consumption data to identify trends and opportunities for further savings.

- Maintain optimal machine settings based on material type, product specification, and production demands.

- Leverage automation and integration with factory energy management systems for centralized control.

- Invest in operator training programs focused on energy-aware operation and troubleshooting.

- Adopt a continuous improvement mindset to upgrade equipment and processes as new technologies emerge.

By embracing these best practices and partnering with Leshan, factories can future-proof their operations and stand out as industry leaders in sustainability.

The Future of Energy-Efficient Blow Molding with Leshan

Leshan’s commitment to R&D ensures that its blow molding machine portfolio keeps pace with evolving energy standards and industrial demands. Emerging trends such as machine learning-based process optimization, IoT-driven predictive maintenance, and next-generation materials promise even greater gains in efficiency and sustainability. Factories adopting Leshan blow molding machines today are well-positioned to excel in tomorrow’s competitive and eco-conscious marketplace.

For modern factories, energy-saving solutions are more than just a cost reduction strategy—they represent a core pillar of responsible manufacturing. Leshan continues to innovate, enabling manufacturers around the world to meet their production goals while minimizing their environmental footprint.