Blow Molding Machine ODM Services for Innovative Product Development

Blow Molding Machine ODM Services for Innovative Product Development

Leshan, a premier blow molding machine manufacturer, offers comprehensive ODM (Original Design Manufacturing) services that empower companies to achieve innovative product development. With decades of engineering expertise, Leshan guides clients through every step of the journey—from initial consultation and concept design to machine customization, mold fabrication, and process optimization. Their ODM capabilities enable rapid prototyping, tailored machine configurations, and seamless integration of automation, ensuring high-quality, scalable production for unique products across industries such as packaging, automotive, medical, and more. Leshan’s machines are distinguished by features like energy-efficient drives, precision control, modularity, and smart connectivity. The company remains at the forefront of technology trends, including multi-layer co-extrusion, sustainable materials, and digital factory integration. Success stories highlight Leshan’s ability to deliver custom solutions, such as lightweight automotive parts and smart pharmaceutical packaging. Clients benefit from Leshan’s global support network, rigorous quality assurance, and a commitment to innovation-driven product differentiation. By choosing Leshan’s ODM services, manufacturers gain a trusted partner dedicated to transforming creative concepts into market-ready products, ensuring long-term competitiveness in the global market.

In the rapidly evolving world of plastic processing and packaging, the demand for uniquely designed products and efficient manufacturing solutions continues to rise. Leshan, a globally recognized blow molding machine manufacturer, stands at the forefront of this trend by offering specialized Original Design Manufacturing (ODM) services. These services are tailored to support innovative product development and provide companies with a technological edge in their respective markets.

Introduction to Blow Molding and ODM Services

The blow molding process is a cornerstone of plastic manufacturing, enabling the mass production of hollow plastic parts such as bottles, containers, and automotive components. Leshan’s advanced blow molding machines harness this process, utilizing cutting-edge engineering and automation to deliver precision, consistency, and scalability.

undefined

Original Design Manufacturing (ODM) is a service model wherein manufacturers like Leshan not only build products to client specifications but also offer complete design solutions. This means customers can leverage Leshan’s expertise to create fully customized blow molding machines and product designs, minimizing the time and resources required for product development.

Why Choose Leshan for Blow Molding Machine ODM

Unmatched Engineering Excellence

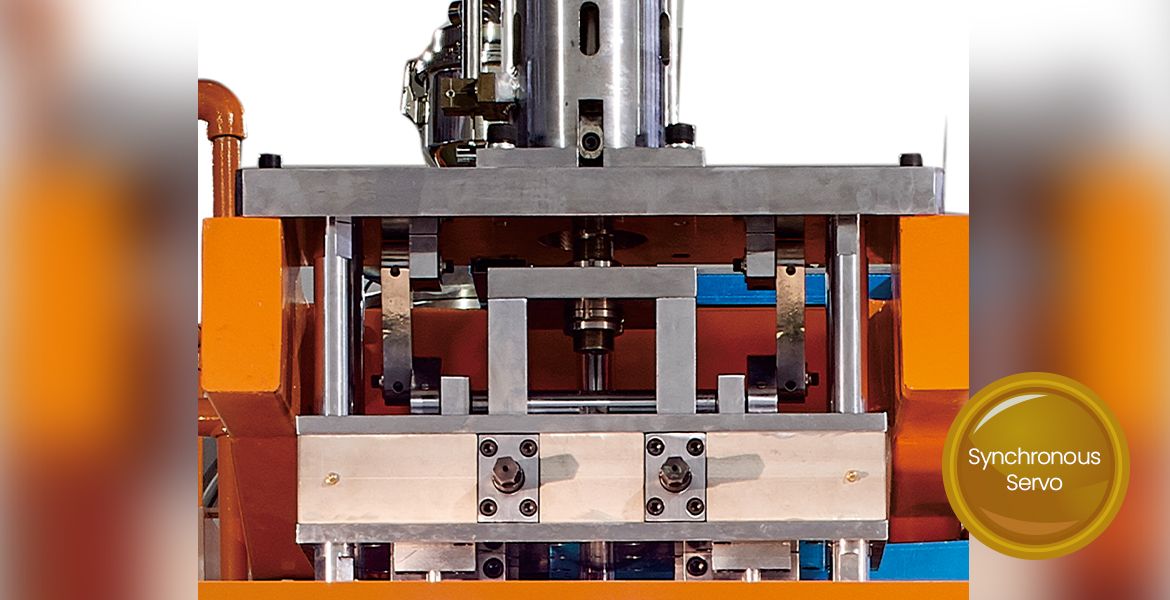

Leshan’s reputation as a leading blow molding machine manufacturer stems from decades of technical experience and relentless innovation. Their engineering team continuously refines machine architecture, adopting the latest advancements in hydraulics, servo control systems, and energy-saving technologies. This positions Leshan as an ideal ODM partner for enterprises seeking reliable, state-of-the-art solutions.

Comprehensive ODM Capabilities

- Product Design Consultation: Leshan’s ODM services begin with an in-depth consultation to understand client objectives, application requirements, and market trends.

- Machine Customization: The company can tailor machine specifications—such as clamping force, mold size, parison programming, and automation levels—to meet unique production demands.

- Mold Development: Leshan offers end-to-end mold design and fabrication, ensuring seamless integration with blow molding machines and optimized product output.

- Process Optimization: Their technical experts assist in fine-tuning the blow molding process for maximum productivity, material efficiency, and product quality.

- After-Sales Support: Global customers benefit from comprehensive training, maintenance, and remote diagnostics for continuous operational excellence.

Innovative Product Development with Leshan ODM

Turning Ideas into Market-Ready Products

Innovation is at the heart of Leshan’s ODM philosophy. The company encourages clients to explore creative product concepts, whether it’s a new bottle shape, a multi-layer container, or a functionally enhanced component. Through collaborative development, Leshan transforms these concepts into production-ready solutions by managing all aspects of machine and mold design.

Leshan’s R&D capabilities are supported by advanced simulation tools and prototyping facilities, enabling rapid iteration and validation of design ideas. This accelerates time-to-market while minimizing development risks.

Case Example: Custom Blow Molding for Specialty Packaging

A global beverage brand approached Leshan to develop a unique bottle with an ergonomic grip and enhanced shelf appeal. Leshan’s ODM team collaborated closely with the client’s design and marketing teams, producing 3D renderings, functional prototypes, and final molds. The tailored blow molding machine, equipped with servo-driven components, delivered high-speed production with repeatable quality—demonstrating Leshan’s ability to deliver customized, innovative manufacturing solutions.

Key Features of Leshan ODM Blow Molding Machines

| Feature | Description |

|---|---|

| Energy Efficiency | Variable frequency drives and energy-saving hydraulic systems reduce power consumption. |

| Precision Control | Advanced parison controllers ensure uniform wall thickness and product consistency. |

| Modularity | Flexible designs allow for modular upgrades and configuration changes as production needs evolve. |

| Automation Integration | Robotic handling, vision inspection, and automated trimming enhance productivity and reduce labor costs. |

| Smart Connectivity | IoT-enabled monitoring for predictive maintenance and real-time performance analysis. |

The ODM Process with Leshan: Step-by-Step

- Needs Assessment: Leshan’s specialists engage with the client to define project goals, product requirements, and production targets.

- Concept Design: Preliminary sketches, CAD models, and process simulations are presented for client review and feedback.

- Engineering: Detailed machine and mold engineering ensures technical feasibility and cost-effectiveness.

- Prototyping: Rapid prototyping enables early-stage product testing and validation.

- Tooling & Manufacturing: Precision mold fabrication and machine assembly are performed in-house for optimal integration.

- Commissioning & Support: Leshan provides on-site installation, training, and ongoing technical support to ensure project success.

Benefits of Partnering with Leshan ODM Services

- Accelerated Innovation: Leshan’s streamlined process shortens product development cycles, enabling faster launches and competitive advantage.

- Cost Optimization: By leveraging Leshan’s design and manufacturing expertise, clients minimize capital expenditure and avoid costly design errors.

- Quality Assurance: Rigorous quality control and testing ensure high performance and product reliability.

- Market Differentiation: Unique product features and customized machine capabilities help brands stand out in crowded markets.

- Global Reach: Leshan’s international distribution and support network facilitate seamless ODM project execution worldwide.

Applications of Leshan Blow Molding Machines across Industries

Leshan’s ODM blow molding machines are engineered for versatility, serving a wide array of industries:

- Packaging: Bottles, jerry cans, drums, and detergent containers for food, beverage, and household products.

- Automotive: Fuel tanks, ducts, and reservoirs with complex geometries and performance requirements.

- Medical: Sterile containers, laboratory bottles, and pharmaceutical packaging meeting stringent safety standards.

- Toys and Leisure: Lightweight, durable toys, sports equipment, and outdoor products.

- Industrial: Custom containers and tanks for chemicals, lubricants, and industrial fluids.

Technology Trends Shaping Leshan ODM Blow Molding

Leshan invests heavily in research to keep its blow molding machines and ODM services at the technological forefront. Current trends include:

- Multi-Layer Co-Extrusion: Enabling packaging with advanced barrier properties and multi-functional components.

- Biodegradable and Recycled Materials: Processing eco-friendly resins for sustainable packaging and reduced environmental impact.

- Digital Twin and Smart Factory Integration: Virtual modeling and digital monitoring for enhanced process control and traceability.

- High-Speed Automation: Servo-driven and fully automated lines to maximize throughput and consistency.

Customer Success Stories: Leshan ODM in Action

Automotive Lightweighting Initiative

An international automotive OEM sought to reduce vehicle weight through advanced plastic components. Leshan’s ODM team developed a custom blow molding solution for hollow engine ducts, integrating lightweight design with robust mechanical strength. The result was a 20% weight reduction and improved fuel efficiency, exemplifying Leshan’s ability to drive innovation in high-performance applications.

Smart Packaging for Pharmaceuticals

A pharmaceutical packaging company required tamper-evident bottles with integrated RFID tracking. Leshan designed a specialized blow molding machine capable of producing these bottles at scale, incorporating RFID chip insertion and real-time quality inspection. The project underscored Leshan’s strengths in marrying precision engineering with advanced automation.

Global Support and Ongoing Partnership

Leshan’s ODM clients benefit from robust after-sales support that includes on-site installation, operator training, spare parts supply, and remote technical assistance. The company’s global service network ensures rapid response and minimal downtime, securing long-term productivity for manufacturers worldwide.

Why Leshan Stands Out in the ODM Blow Molding Market

- Proven Track Record: Years of successful installations and satisfied clients across continents.

- Innovation-Driven Culture: Continuous investment in R&D and a commitment to exceeding client expectations.

- End-to-End Solutions: From initial concept to ongoing maintenance, Leshan provides a one-stop-shop for blow molding innovation.

- Custom Engineering: Machines, molds, and integrated lines are designed to meet the unique needs of every project.

- Global Vision: Leshan’s international perspective ensures compliance with regulatory standards and market preferences worldwide.

Join the Future of Plastic Manufacturing with Leshan ODM

For companies seeking to bring next-generation products to life, Leshan’s ODM blow molding machine services offer unmatched value. By combining engineering prowess, manufacturing excellence, and a customer-centric approach, Leshan empowers innovators to realize their product visions and maintain a competitive edge in their industries.

Tags:automatic blow molding machine,HDPE bottle blow molding machine supplier,automatic blow molding machine application