Blow Molding Machine Solutions for Advanced Plastics

Blow Molding Machine Solutions for Advanced Plastics

Leshan, a leading blow molding machine manufacturer, delivers advanced solutions for the plastics industry, focusing on innovation, sustainability, and customer-driven engineering. They offer a comprehensive portfolio of machines for extrusion, injection, and stretch blow molding, suitable for diverse applications from packaging and automotive to medical and industrial sectors. Leshan’s machines feature state-of-the-art automation, energy-efficient designs, and compatibility with modern polymers, including recycled and bio-based materials. Their technology supports smart manufacturing with IoT integration, quality assurance systems, and high-speed production capabilities. Leshan’s commitment extends to after-sales service, operator training, and custom engineering partnerships to address emerging challenges. Global manufacturers benefit from Leshan’s expertise in achieving high productivity, consistent product quality, and optimized operational performance. For those seeking reliable, innovative blow molding solutions for advanced plastics, Leshan stands out as a trusted partner.

In today's fast-evolving plastics industry, precision, efficiency, and reliability are paramount. Leshan stands at the forefront as a blow molding machine manufacturer, delivering advanced solutions tailored to the diverse needs of the market. With decades of expertise and a commitment to innovation, Leshan’s blow molding machines have empowered manufacturers worldwide to achieve superior product quality, sustainable production, and optimized operational performance.

About Leshan: Pioneering Blow Molding Technologies

Leshan, a renowned blow molding machine manufacturer, has built its reputation on technological excellence and customer-centric solutions. The company specializes in designing, engineering, and manufacturing a wide range of blow molding machines that cater to various sectors such as packaging, automotive, medical, consumer goods, and industrial components.

From small-scale production units to large industrial plants, Leshan’s portfolio encompasses machines for extrusion blow molding, injection blow molding, and stretch blow molding, each engineered to deliver consistent quality and high productivity. Leshan’s commitment to sustainability is evident in their energy-efficient designs and solutions for processing recycled materials.

The Fundamentals of Blow Molding

Blow molding is a manufacturing process in which hollow plastic parts are formed by inflating a heated plastic tube until it takes the shape of a mold cavity. The process is highly versatile, enabling the production of bottles, containers, tanks, and specialized engineering components. Leshan’s blow molding machines are designed to support advanced plastics, offering flexibility for processing materials such as HDPE, PET, PP, PVC, and engineering polymers.

undefined

- Extrusion Blow Molding: Ideal for large containers, automotive parts, and industrial components.

- Injection Blow Molding: Suitable for precision parts, pharmaceutical packaging, and small bottles.

- Stretch Blow Molding: Primarily used for producing PET bottles with high clarity and strength.

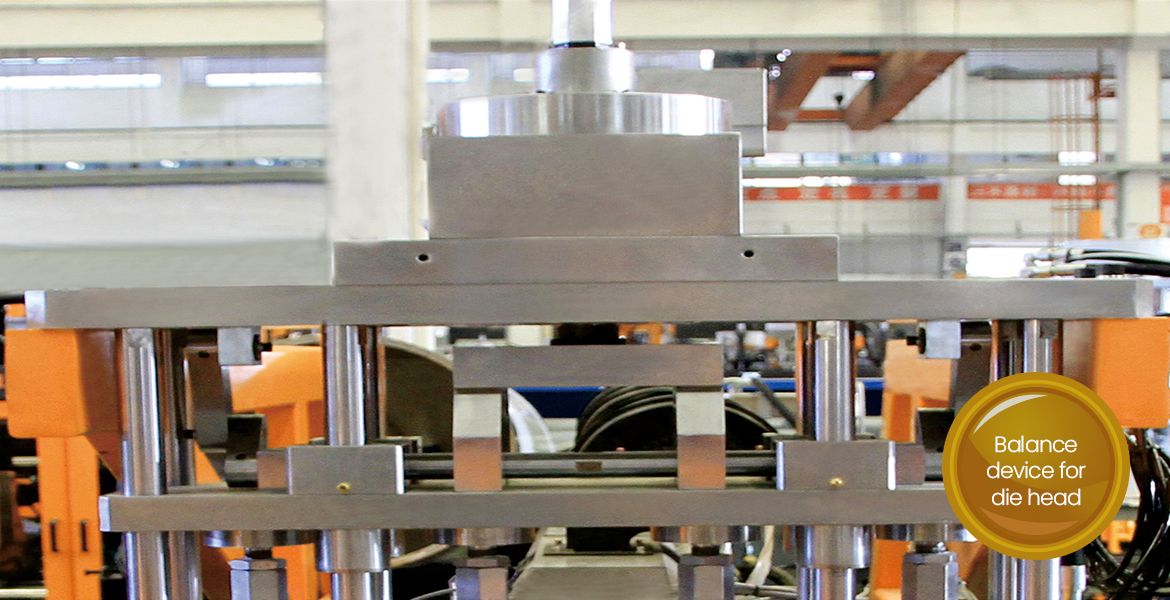

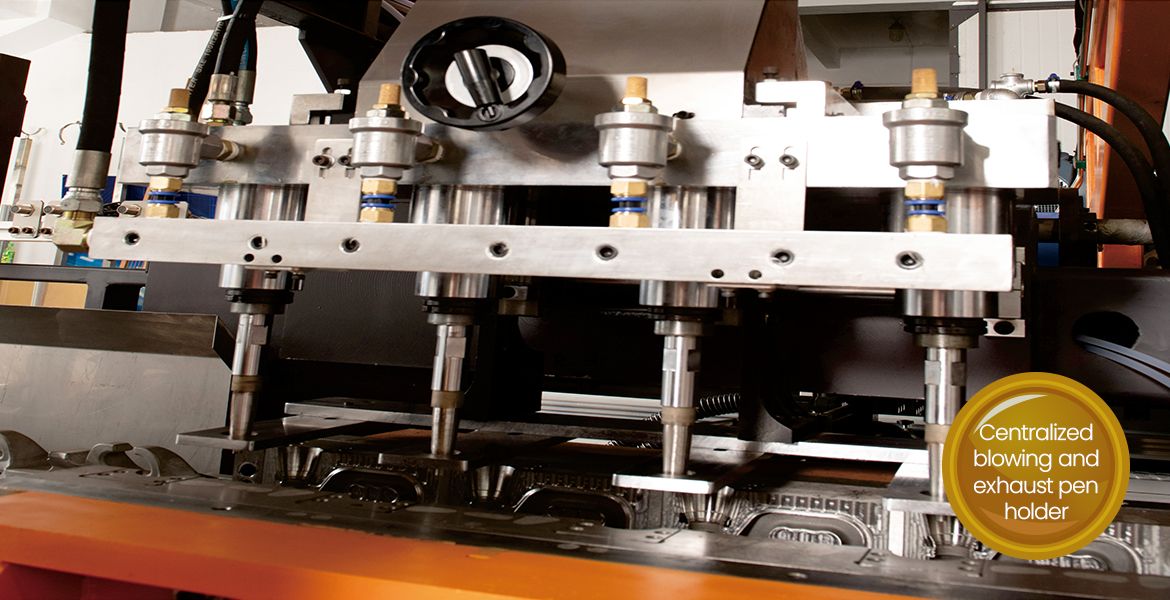

Advanced Features of Leshan Blow Molding Machines

Precision Engineering and Automation

Leshan integrates the latest automation technologies into their blow molding machines, including programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for seamless control and monitoring. The machines feature closed-loop systems for temperature, pressure, and cycle time regulation, ensuring repeatable results and minimizing defects.

Energy-Efficient and Eco-Friendly Design

Recognizing the importance of sustainability, Leshan has developed blow molding machines with energy-saving features such as servo-driven systems, efficient heating elements, and optimized cooling circuits. These innovations not only reduce operating costs but also support industry efforts to minimize environmental impact.

Material Versatility

Leshan machines are engineered to process a variety of advanced plastics, including recycled and bio-based polymers. The company’s research and development team collaborates closely with material suppliers to ensure compatibility and optimal performance across new polymer grades.

Custom Solutions for Industry Applications

Every industry faces unique challenges in blow molded product design and manufacturing. Leshan offers custom-configured machines and tooling to address specific requirements, from thin-wall packaging to complex automotive ducting and medical device housings. Their engineering team works closely with clients to optimize cycle times, material usage, and product consistency.

Leshan’s Technological Innovations

Smart Manufacturing Integration

Modern manufacturing demands connectivity and data-driven decision-making. Leshan’s blow molding machines are IoT-enabled, allowing remote monitoring, diagnostics, and predictive maintenance. Through real-time analytics, users can optimize process parameters, track production trends, and identify potential issues before they impact output quality.

High-Speed Production Capabilities

For industries requiring mass production, Leshan has developed high-speed blow molding machines with multi-cavity molds and rapid cooling systems. These features enable manufacturers to achieve higher throughput without sacrificing dimensional accuracy or product integrity.

Quality Assurance

Quality control is integral to Leshan’s manufacturing philosophy. Each machine is equipped with in-line inspection systems for monitoring wall thickness, weight, and dimensional tolerances. Automated rejection mechanisms ensure only products meeting stringent quality criteria proceed to packaging.

Applications Across Industries

| Industry | Application Examples | Leshan Machine Solutions |

|---|---|---|

| Packaging | Bottles, jars, drums | Extrusion, injection, stretch blow molding machines with multi-cavity configurations |

| Automotive | Ducts, reservoirs, fuel tanks | Large-format extrusion blow molding systems with precision control |

| Medical | Pharmaceutical bottles, diagnostic containers | Cleanroom-compatible injection blow molding machines |

| Consumer Goods | Toys, household containers | Custom-designed single- and multi-station blow molding machines |

| Industrial | Chemical storage tanks, equipment housings | Heavy-duty extrusion blow molding solutions |

Case Studies: Leshan in Action

Leading manufacturers worldwide rely on Leshan blow molding machines for mission-critical production. For example, a global beverage company increased PET bottle output by 30% after integrating Leshan’s stretch blow molding system, while an automotive supplier achieved tighter tolerances on air ducts using Leshan’s extrusion blow molding equipment. In the medical sector, Leshan’s cleanroom-ready machines enabled compliant production of sterile packaging for pharmaceuticals.

After-Sales Support and Service

Leshan’s commitment extends beyond machine delivery. Their comprehensive after-sales service includes installation, commissioning, operator training, and ongoing technical support. Global service networks and remote assistance platforms ensure timely resolution of issues and uninterrupted production.

Custom Engineering and R&D Partnerships

To address emerging challenges in plastics processing, Leshan collaborates with clients on joint R&D projects. Whether developing new tooling for innovative product shapes or optimizing machine parameters for novel materials, Leshan’s engineering experts are dedicated to advancing blow molding technology in partnership with industry leaders.

The Leshan Advantage

- Decades of experience in blow molding machine manufacturing

- Comprehensive range of machines for all major blow molding processes

- Cutting-edge automation and Industry 4.0 integration

- Sustainable design and energy efficiency

- Global service and support network

- Expertise in custom solutions for advanced plastics applications

Why Choose Leshan for Advanced Plastics Blow Molding?

Leshan’s focus on innovation, quality, and customer collaboration has positioned the company as a trusted partner in the plastics industry. By choosing Leshan, manufacturers gain access to state-of-the-art blow molding technology, experienced engineering support, and a pathway to achieving production excellence in an increasingly competitive market.

Contact Leshan

To learn more about Leshan’s blow molding machine solutions for advanced plastics, or to discuss your specific application requirements, reach out directly to the Leshan team. Our experts are ready to assist you in selecting the optimal machine configuration for your production goals.

Tags:HDPE bottle blow molding machine supplier,EBM blow molding machine application,automatic blow molding machine application,full electric blow molding machine supplier