Bottle blow molding machine durability for long-term reliability

Bottle blow molding machine durability for long-term reliability

Durability and long-term reliability are crucial factors in choosing blow molding machinery for bottle manufacturing. Leshan, a leading blow molding machine manufacturer, distinguishes itself through advanced engineering, high-quality materials, and robust manufacturing processes that maximize machine lifespan and minimize downtime. By integrating hardened alloys, corrosion-resistant steels, precision machining, and intelligent control systems, Leshan ensures every component is optimized for continuous, high-stress operation. Comprehensive maintenance support, modular designs for easy repairs, and proactive training resources further extend machine life and reduce operational costs. Leshan’s commitment to customer feedback, environmental responsibility, and global technical support underpins its reputation for reliable, sustainable solutions. Manufacturers partnering with Leshan benefit from machines designed for decades of service, supporting consistent, efficient, and eco-friendly bottle production in rapidly evolving markets.

Blow molding technology has revolutionized the packaging industry, enabling the mass production of plastic bottles with remarkable precision and efficiency. Among the leading manufacturers in this sector, Leshan stands out for its commitment to durability and long-term reliability in their bottle blow molding machines. As businesses increasingly demand robust solutions to ensure consistent production and minimal downtime, understanding the factors that contribute to machine durability becomes essential. This article delves deep into Leshan's engineering philosophy, material selection, manufacturing processes, and maintenance strategies that make their blow molding machines a preferred choice for sustainable operations.

Understanding Blow Molding Machine Durability

Durability in blow molding machines is not just a matter of lifespan; it directly affects operational costs, product quality, and overall factory efficiency. For bottle manufacturers, investing in reliable equipment means fewer interruptions, lower repair expenses, and consistent output that meets market demand. Leshan, as a renowned blow molding machine manufacturer, places durability at the core of its product development, aiming to exceed industry standards and customer expectations.

Key Factors Influencing Machine Durability

- Material Selection: The foundation of Leshan's durable machines lies in the careful selection of high-strength alloys, corrosion-resistant steels, and advanced polymers. Each component, from the extrusion barrel to the mold frame, undergoes rigorous testing to ensure optimal performance under continuous stress and heat.

- Precision Engineering: Leshan employs state-of-the-art CNC machining and laser measurement systems to achieve tight tolerances in critical areas, reducing wear and tear and extending service intervals. This precision ensures that parts fit perfectly, moving smoothly without excess friction.

- Thermal Management: Heat is a constant challenge in blow molding. Leshan designs its machines with advanced cooling systems, including water jackets and heat sinks, to maintain stable operating temperatures and prevent premature degradation of components.

- Wear-Resistant Surfaces: Strategic use of surface treatments such as hardening, nitriding, and specialized coatings protects against abrasion, chemical attack, and fatigue, especially in high-contact zones like mold cavities and screw barrels.

- Robust Control Systems: Integrated PLCs and sensor arrays monitor machine performance in real time, providing early warnings for maintenance and ensuring that operating parameters remain within safe limits, safeguarding both the equipment and the end product.

Leshan's Manufacturing Excellence

Leshan's reputation as a trusted blow molding machine manufacturer is built on decades of innovation and a relentless pursuit of quality. Its production facilities integrate advanced automation with skilled craftsmanship, creating machines that are both technologically sophisticated and robust. Every stage of assembly is subject to stringent QA procedures, from the casting of frames to the calibration of hydraulic systems.

The company invests heavily in R&D, continually refining designs to minimize stress concentrations and enhance load distribution. Leshan's engineers utilize finite element analysis (FEA) to simulate operational conditions, identifying potential failure points and reinforcing them before machines reach the market.

undefined

Material Science in Leshan Blow Molding Machines

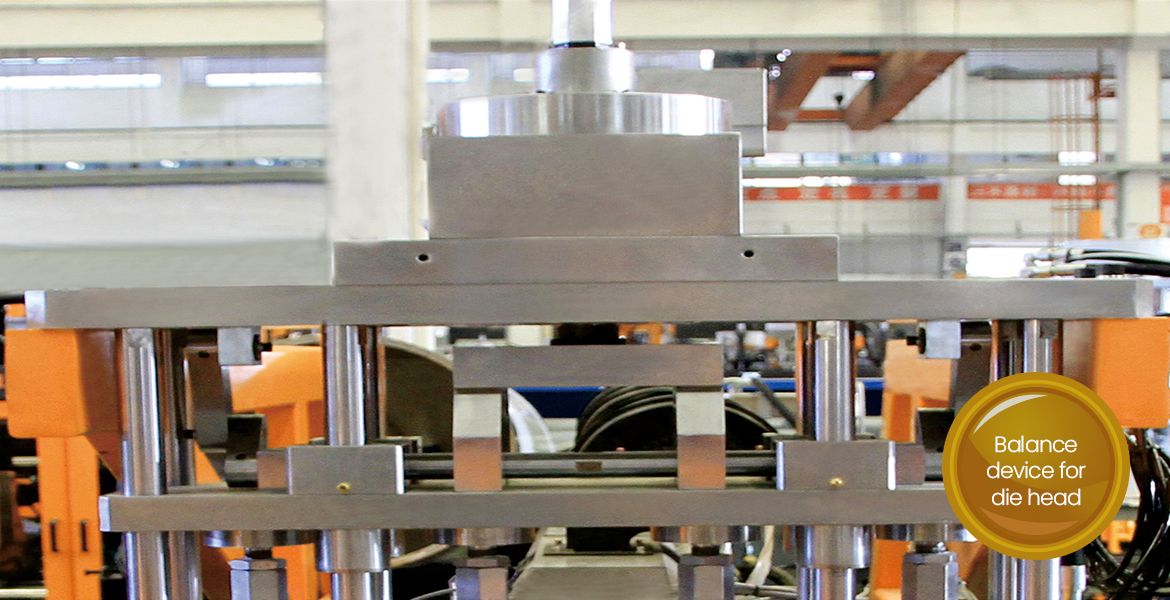

Material science is the backbone of any durable industrial machine. Leshan sources high-grade metals and specialty plastics from reputable suppliers, ensuring traceability and consistency. Key machine components such as the extrusion screw, die head, and mold plates are fabricated from hardened tool steel, chosen for its ability to withstand repeated thermal cycling and mechanical impact.

For non-structural parts, Leshan employs engineered polymers that offer excellent chemical resistance and dimensional stability, reducing the risk of deformation and leaks. Protective coatings are applied using advanced deposition methods, forming a barrier against corrosive resins and cleaning agents commonly used in plastic bottle manufacturing.

Table: Leshan Material Choices for Key Components

| Component | Primary Material | Durability Feature |

|---|---|---|

| Extrusion Screw | Hardened Steel Alloy | Wear Resistance, Fatigue Strength |

| Mold Frame | High-Carbon Steel | Impact Toughness, Stability |

| Die Head | Stainless Steel | Corrosion Resistance |

| Hydraulic Cylinder | Chromium-Plated Steel | Surface Hardness |

| Control Panel Housing | Reinforced Polymer | Chemical Resistance |

Design Innovations for Reliability

Leshan's engineers focus on simplifying maintenance and minimizing downtime. Modular components allow for quick replacement, while self-lubricating bushings and sealed bearings reduce the need for frequent lubrication. This approach not only extends the machine's operational life but also lowers the total cost of ownership for bottle manufacturers.

Redundant safety systems, including pressure relief valves and emergency stop circuits, are standard. Leshan's programmable controls offer diagnostic capabilities, enabling predictive maintenance before minor issues escalate into costly breakdowns.

Maintenance Strategies for Longevity

Machine durability is closely linked to regular and proactive maintenance. Leshan supports its customers with detailed service manuals, training programs, and remote assistance. The company recommends a maintenance schedule that encompasses:

- Daily checks for lubricants, coolant levels, and sensor readings

- Weekly inspection of wear-prone components such as screws, barrels, and hydraulic seals

- Monthly calibration of control systems and temperature regulation devices

- Annual replacement of consumables and comprehensive cleaning of mold cavities

By adhering to these protocols, Leshan machine operators can significantly prolong equipment life and maintain optimal performance.

Case Studies: Leshan Machines in Real-World Applications

Across the globe, Leshan blow molding machines operate in high-demand environments, from beverage bottling plants to pharmaceutical packaging lines. Customers regularly report extended machine lifespans, often exceeding a decade of continuous service with minimal major repairs. These results stem from the meticulous design and maintenance support provided by Leshan.

For example, a leading dairy producer in Southeast Asia uses Leshan machines for 24/7 operation. Thanks to robust construction and automated monitoring, downtime has been reduced by 40%, while overall equipment effectiveness (OEE) remains well above industry benchmarks.

Continuous Improvement and Customer Feedback

Leshan's dedication to long-term reliability is reinforced by active collaboration with its clients. Feedback mechanisms enable the company to gather data on machine performance, wear patterns, and operational challenges. This information fuels iterative improvements in machine design, spare parts logistics, and user support platforms.

Periodic upgrades and retrofit kits are offered to existing customers, ensuring compatibility with new materials and processes as market demands evolve. Leshan's customer-centric approach is instrumental in fostering lasting partnerships and mutual growth.

The Economic Impact of Durable Blow Molding Machines

Investing in a durable Leshan blow molding machine yields significant economic benefits. Reduced maintenance expenses, lower energy consumption, and fewer production stoppages translate directly into increased profitability for bottle manufacturers. Moreover, the enhanced reliability supports just-in-time manufacturing strategies, aligning supply with fluctuating demand.

From a sustainability perspective, longer machine lifespans also decrease the environmental footprint of manufacturing operations. Leshan's continuous focus on energy-efficient designs and recyclable materials further amplifies these advantages, supporting corporate sustainability goals.

Industry Trends and Future Outlook

The evolution of bottle blow molding is driven by advancements in smart manufacturing, IoT integration, and eco-friendly materials. Leshan is at the forefront of this transformation, embedding sensors and cloud connectivity into its machines for real-time monitoring and predictive analytics. These features empower operators to optimize productivity and identify maintenance needs well before failures occur.

As the packaging industry transitions towards biodegradable polymers and lightweight bottle designs, Leshan is developing specialized machine configurations to handle new material requirements without compromising durability. Continuous training and support ensure that customers can leverage these innovations for sustained competitive advantage.

Summary Table: Leshan's Durability Features

| Durability Feature | Benefit |

|---|---|

| High-Grade Materials | Extended Lifespan, Reduced Wear |

| Precision Engineering | Minimized Maintenance, Consistent Quality |

| Advanced Cooling Systems | Temperature Stability, Prevents Overheating |

| Intelligent Controls | Early Fault Detection, Predictive Maintenance |

| Modular Design | Easy Repairs, Fast Upgrades |

Customer Support and Global Reach

One of Leshan's distinguishing traits is its comprehensive customer support infrastructure. With service centers and technical teams spanning continents, Leshan ensures timely assistance, genuine spare parts, and on-site training for machine operators. This global presence enables manufacturers everywhere to maintain peak productivity and machine reliability, regardless of location.

Remote diagnostics, online troubleshooting, and multilingual documentation further enhance the user experience, making Leshan a truly international partner for bottle manufacturers seeking long-term reliability in their blow molding operations.

Training and Technical Resources

To maximize the longevity of its machines, Leshan offers extensive training modules for technicians and operators. These programs cover everything from routine maintenance to advanced troubleshooting and process optimization. By equipping personnel with the right knowledge, Leshan helps prevent common errors that could lead to premature machine failure.

Digital resources, including video tutorials, interactive manuals, and expert webinars, are regularly updated and accessible to clients worldwide. This proactive education strategy is a key pillar of Leshan's durability promise.

Environmental Considerations in Durable Machine Design

Modern bottle manufacturers are increasingly conscious of their environmental impact. Leshan designs its blow molding machines to minimize energy consumption, waste generation, and resource use. Efficient motors, optimized heating elements, and intelligent process controls reduce carbon emissions and operating costs.

Durable machines also contribute to sustainability by reducing the frequency of equipment replacement and disposal. Leshan's recycling programs for end-of-life parts and materials further reinforce its commitment to responsible manufacturing practices.

Advanced Testing and Certification

Every Leshan blow molding machine undergoes a battery of stress tests, endurance trials, and safety inspections before delivery. Compliance with global standards such as CE, ISO, and UL certificates guarantees reliability and operator safety. Regular audits ensure that Leshan's quality management systems remain at the cutting edge of industry requirements.

Clients receive detailed test reports and certification documents, providing transparency and confidence in the durability of their investments.

Custom Solutions for Unique Needs

Leshan recognizes that bottle manufacturers face diverse operational challenges. The company offers tailored blow molding solutions, engineering machines to handle specific materials, bottle geometries, and production environments. Customization includes reinforced frames, variable speed drives, and specialized sensor arrays for complex applications.

This flexibility ensures that every Leshan machine delivers optimal durability and reliability, regardless of production scale or product specification.

Long-Term Partnership for Success

Leshan's philosophy extends beyond the initial sale, focusing on building enduring relationships with its clients. Regular performance reviews, upgrade recommendations, and strategic consultations help manufacturers adapt to evolving market conditions while maintaining machine reliability. This ongoing partnership is central to Leshan's leadership in the blow molding sector.

Summary of Leshan's Approach to Durable Blow Molding Machines

Leshan's bottle blow molding machines are engineered for maximum durability and long-term reliability. Through exceptional material science, precision manufacturing, modular design, and robust customer support, Leshan delivers solutions that minimize downtime, reduce maintenance costs, and support sustainable production. Their proactive approach to innovation and training ensures customers remain at the forefront of industry trends, confident in the longevity of their equipment.

Tags:EBM blow molding machine application,blow molding machine,automatic blow molding machine