Bottle blow molding machine sustainability for eco-friendly manufacturing

Bottle blow molding machine sustainability for eco-friendly manufacturing

Leshan, a leading blow molding machine manufacturer, is at the forefront of sustainable, eco-friendly bottle manufacturing. By integrating advanced energy-efficient designs, supporting recycled and bio-based materials, and minimizing waste through smart automation, Leshan’s machines dramatically lower the environmental impact of plastic bottle production. The company’s closed-loop systems enable water and material conservation, while its focus on design-for-recycling enhances end-of-life bottle circularity. Leshan’s partnerships, training programs, and comprehensive life cycle assessments empower clients to exceed global sustainability standards. Case studies highlight significant reductions in carbon footprint and water use. As Leshan continues to innovate in areas such as AI-driven optimization and biodegradable plastics processing, it drives the next generation of green manufacturing and shapes a more sustainable future for the packaging industry.

In an era marked by increasing environmental concerns and the urgent need for sustainable industrial practices, the manufacturing of plastic bottles has come under intense scrutiny. As a leading blow molding machine manufacturer, Leshan has embraced the challenge of creating innovative, efficient, and eco-friendly solutions for bottle production. This article explores how Leshan integrates sustainability into the heart of its blow molding machine technologies, transforming the plastics industry and advancing global efforts toward greener manufacturing.

Understanding Blow Molding and Its Environmental Impact

Bottle blow molding is a critical process within the packaging industry, shaping plastic into containers used for beverages, personal care products, cleaning agents, and more. Traditionally, this process has been resource-intensive, consuming substantial energy and raw materials, often generating waste and emissions. The environmental impact of blow molding includes:

hdpe hydraulic plastic blow molding machine

full electric ebm machine

ebm complete machine

automa blow molding machine manufacturer

tornado full electric ebm machine

undefined

- High energy consumption during the heating and forming stages

- Use of virgin plastics contributing to fossil fuel depletion

- Production waste and off-spec products

- Challenges in recycling multi-layer or opaque bottles

Recognizing these issues, Leshan has pioneered a shift toward sustainable blow molding practices that prioritize resource conservation, circularity, and reduced environmental footprint.

Leshan’s Commitment to Sustainable Manufacturing

Eco-Conscious Machine Design

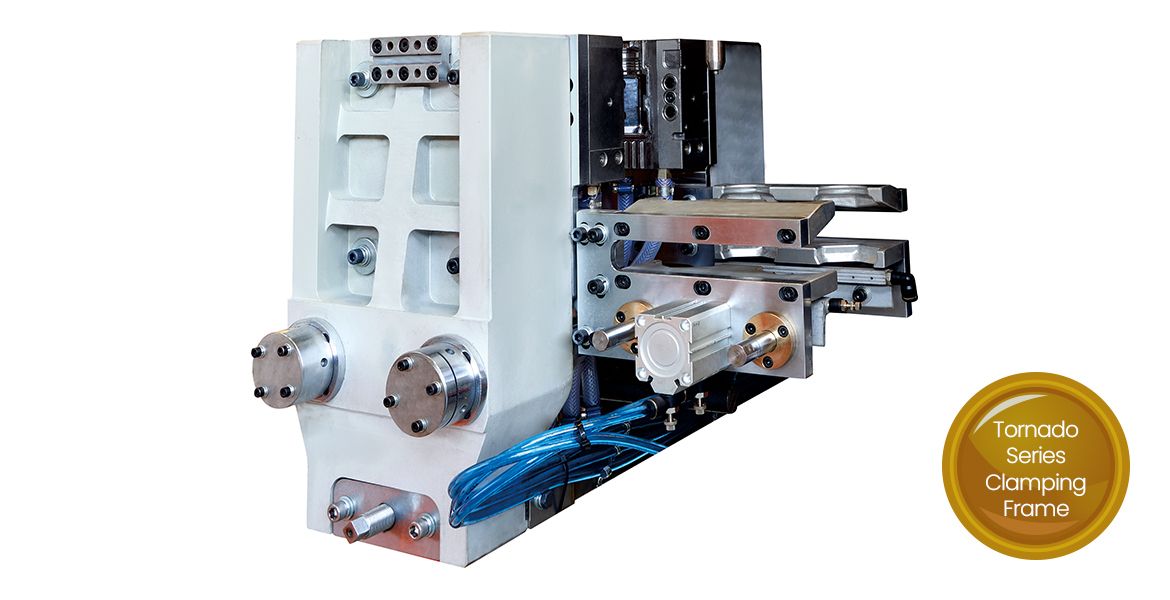

Leshan’s engineering philosophy focuses on creating blow molding machines that minimize energy use and material waste. Key design aspects include:

- Energy-Efficient Heating: Advanced infrared and electric heating systems reduce overall energy demand.

- Servo Motor Technology: Precision servo motors optimize power use across all mechanical movements, limiting unnecessary consumption.

- Lightweight Construction: Modular frames and lightweight components cut down the embodied energy of each machine.

Integration of Recycled Materials

Leshan actively supports the use of post-consumer recycled (PCR) plastics and bio-based materials. Its blow molding machines are engineered for compatibility with a wide array of resins, empowering manufacturers to:

- Seamlessly process PCR/PET and bio-resins alongside traditional plastics

- Reduce reliance on virgin petrochemical resources

- Enhance the recyclability of end products

Technological Innovations Driving Sustainability

Smart Automation and Waste Reduction

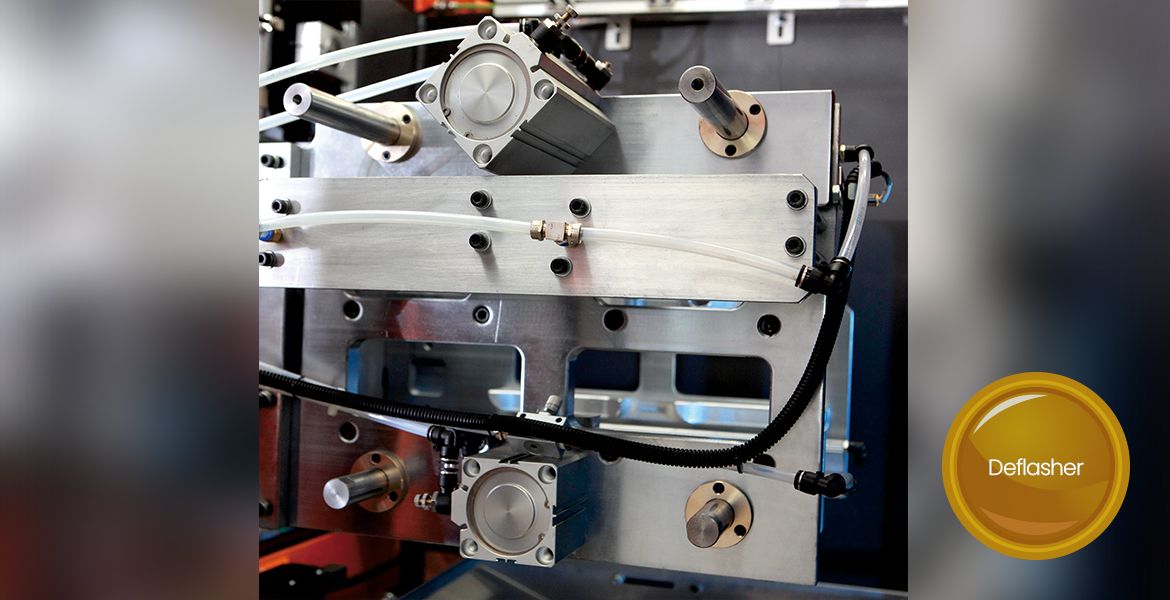

Through the adoption of intelligent control systems and real-time monitoring, Leshan’s machines enable operators to precisely manage every phase of bottle production. Benefits include:

- Minimized defective output through automated quality checks

- Optimized material distribution, reducing resin usage

- Fast changeover features, lowering downtime and scrap

Energy Recovery and Reuse

Leshan incorporates energy recovery modules into its blow molding machines. These systems capture excess heat and kinetic energy, redirecting them to pre-heating or auxiliary processes, resulting in:

- Significant reductions in electricity demand

- Lower production costs for manufacturers

- Decreased greenhouse gas emissions

Material Circularity and Sustainable Bottle Design

Closed-Loop Manufacturing

Central to Leshan’s sustainability strategy is the facilitation of closed-loop manufacturing models. Leshan collaborates with clients to establish systems where production scrap and post-consumer bottles are reprocessed into new feedstock, supporting a truly circular plastics economy.

Design for Recycling

Leshan’s blow molding technology supports mono-material bottle designs and clear labeling, simplifying the recycling process. This proactive design philosophy leads to:

- Higher recycling rates for finished bottles

- Reduced contamination in recycling streams

- Greater acceptance from eco-conscious consumers and regulators

Enhancing Resource Efficiency in Blow Molding

Water Management

Water is essential for cooling in blow molding operations. Leshan machines are equipped with closed-loop cooling circuits that minimize water usage and eliminate discharge. Features include:

- Advanced chillers with water recirculation

- Smart sensors to detect leaks or inefficiencies

- Significant reduction in water footprint per bottle produced

Material Optimization

Leshan utilizes simulation and digital twin technologies to model and optimize bottle wall thicknesses, reducing unnecessary resin use while maintaining product strength. This ensures:

- Lower plastic consumption without compromising quality

- Reduced shipping weights and carbon emissions in logistics

- Cost savings for manufacturers and end users

Renewable Energy and Low-Carbon Operations

Green Manufacturing Facilities

Leshan is committed to powering its manufacturing facilities with renewable energy sources such as solar and wind. The company also encourages clients to explore on-site renewable energy integration, further decreasing the life-cycle emissions of bottle production.

Low-Emission Logistics

By optimizing supply chains and prioritizing local sourcing of components, Leshan reduces transportation distances and associated carbon output. The company also designs compact machines that require less packaging and enable more efficient shipping.

Supporting Customers’ Sustainability Goals

Life Cycle Assessment (LCA) Services

Leshan provides comprehensive LCA services to help customers quantify the environmental benefits of using its blow molding machines. These analyses highlight:

- Reduced energy, water, and material consumption per bottle

- Comparative carbon footprint against conventional technologies

- Compliance with global sustainability standards

Training and Knowledge Transfer

Leshan offers ongoing training in sustainable manufacturing for operators and engineers. This empowers clients to maximize the efficiency and eco-friendliness of their blow molding operations, promoting industry-wide best practices.

Industry Partnerships and Compliance

Collaboration with Environmental Organizations

Leshan partners with NGOs, recyclers, and industry groups to advance sustainable packaging and circular economy initiatives. These collaborations accelerate the adoption of responsible bottle production methods worldwide.

Regulatory Alignment

Leshan’s blow molding technologies are designed to meet or exceed the world’s strictest environmental regulations, including:

- EU eco-design directives

- China’s Green Manufacturing Standards

- U.S. EPA and FDA guidelines for packaging

Case Studies: Real-World Sustainability Impacts

Client Success Story: Transition to 100% Recycled PET

A leading beverage company partnered with Leshan to transition its bottle production to 100% recycled PET. Leveraging Leshan’s advanced blow molding machines, the client achieved:

- 50% reduction in carbon footprint compared to virgin resin bottles

- Improved bottle clarity and strength

- Recognition from global environmental certifications

Regional Impact: Water Savings in Arid Environments

In water-scarce regions, Leshan’s closed-loop cooling solutions have enabled manufacturers to cut water use by up to 80%, protecting local ecosystems and reducing operational costs.

Future Directions: Driving the Next Wave of Eco-Friendly Manufacturing

Continuous Innovation

Leshan invests heavily in R&D to develop next-generation blow molding technologies with even greater sustainability benefits, including:

- Integration of AI for predictive maintenance and further energy optimization

- Development of machines for biodegradable and compostable plastics

- Expansion of cloud-based monitoring for global sustainability benchmarking

Industry Leadership

Through thought leadership, technical excellence, and unwavering commitment to sustainability, Leshan aims to redefine the standards of bottle manufacturing for a better, greener future.