Can an Automatic EBM Machine Reduce Manufacturing Costs

Can an Automatic EBM Machine Reduce Manufacturing Costs

Automatic EBM (Extrusion Blow Molding) machines, such as those designed by Leshan, offer substantial opportunities for manufacturers to reduce production costs across multiple operational dimensions. By automating critical stages of the blow molding process, these machines minimize labor dependency, reduce material waste, and deliver higher throughput with improved energy efficiency. Enhanced quality control systems embedded in Leshan's equipment ensure consistent standards, reducing the likelihood of costly defects and reworks. Case studies from various industries demonstrate that businesses can achieve dramatic reductions in labor expenses, energy consumption, and scrap rates while accelerating their return on investment within as little as 12 to 24 months. While initial capital investment and system integration present challenges, Leshan’s robust support and scalable solutions mitigate these concerns. Overall, automation with Leshan’s EBM machines not only drives manufacturing cost savings but also supports companies in meeting sustainability targets and remaining competitive in an increasingly automated global market.

In the ever-evolving landscape of plastic manufacturing, reducing operational costs is a primary objective for companies striving to maintain competitiveness and profitability. Leshan, a renowned blow molding machine manufacturer, has been at the forefront of innovation, delivering cutting-edge automatic Extrusion Blow Molding (EBM) machines to clients worldwide. But can investing in automatic EBM machines truly help manufacturers lower their production costs? This article explores the mechanisms, benefits, and financial implications of adopting automated EBM solutions, focusing on the expertise and technology offered by Leshan.

Understanding Automatic EBM Machines

Automatic EBM (Extrusion Blow Molding) machines represent a significant leap in efficiency and precision within the plastics industry. These machines are engineered to automate the complete process of forming hollow plastic products such as bottles, containers, and drums. Leshan’s line of EBM machines integrates advanced robotics, programmable logic controllers (PLCs), and intelligent monitoring systems to facilitate seamless, unattended production cycles.

undefined

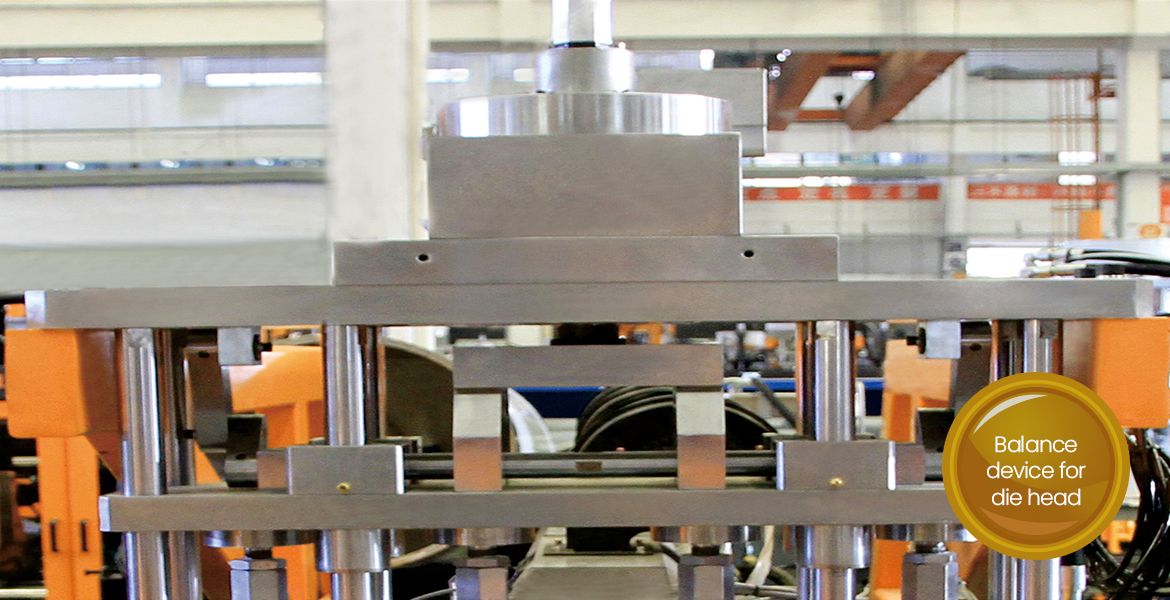

The core of the EBM process involves three main stages: extrusion, molding, and ejection. Automation optimizes each phase, minimizing human intervention and reducing variability. With Leshan’s technology, material handling, parison cutting, mold clamping, and product ejection are all synchronized and precisely controlled, ensuring consistent quality and throughput.

Key Cost Components in Traditional Manufacturing

To understand the cost-saving advantages of automatic EBM machines, it is crucial to examine where expenses typically accrue in conventional manufacturing setups. The following areas are particularly significant:

- Labor Costs: Manual operations require more operators, leading to higher wage bills and training costs.

- Material Waste: Human error and inconsistent cycle times often result in increased scrap rates and inefficient material utilization.

- Downtime: Machines that depend heavily on manual intervention are prone to more frequent and extended stoppages, impacting overall productivity.

- Energy Usage: Inefficient equipment and suboptimal cycle planning can lead to excessive electricity consumption.

- Quality Control: Manual inspections may miss defects, resulting in costly rework or customer returns.

How Leshan's Automatic EBM Machines Address Cost Challenges

Labor Efficiency and Workforce Optimization

One of the most prominent advantages of Leshan’s automatic EBM machines is a dramatic reduction in labor requirements. Automation allows manufacturers to operate multiple machines with fewer personnel. Advanced interfaces and user-friendly HMI (Human Machine Interface) systems enable a single operator to oversee several production lines simultaneously, drastically cutting down on labor expenses.

Additionally, since these machines are less reliant on skilled operators for daily tasks, companies can redirect their workforce to higher-value activities such as quality analysis or process engineering.

Material Savings and Scrap Reduction

Leshan’s machines leverage precise controls to ensure the exact amount of raw material is extruded for each product. This accuracy translates into lower material wastage and minimized scrap rates. Real-time sensors and automated feedback loops detect inconsistencies and make adjustments on-the-fly, further safeguarding against costly production errors.

By utilizing servo-driven systems and optimized parison control, Leshan ensures uniform wall thickness and weight distribution, contributing to material efficiency and cost savings on resin consumption.

Increased Production Throughput

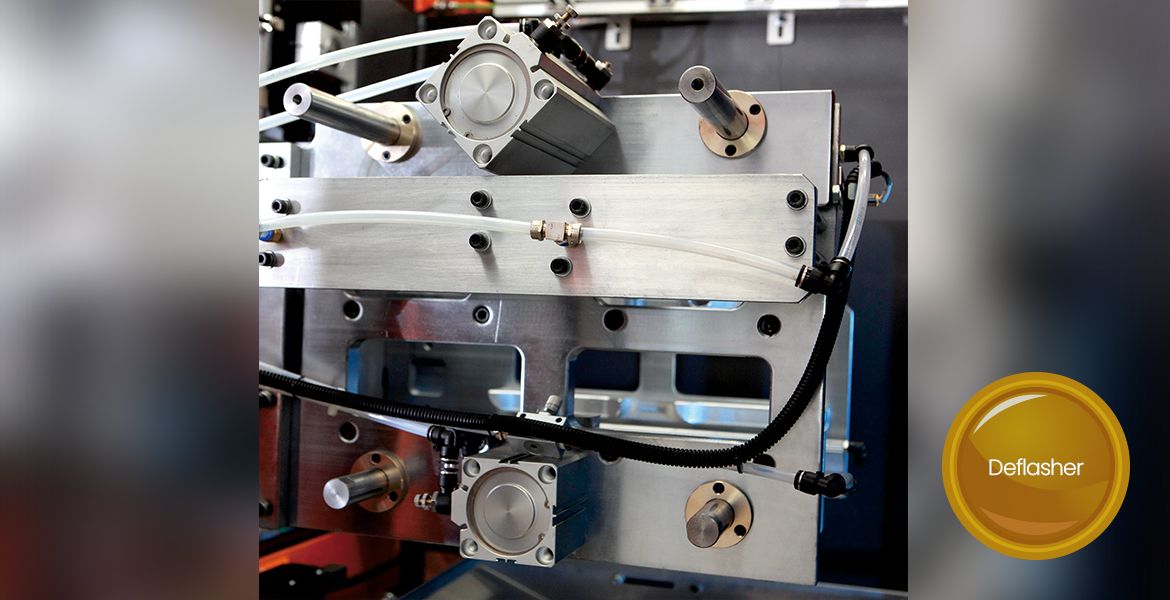

Automated EBM machines from Leshan are engineered for speed and reliability. With features like fast cycle times, automated mold changes, and integrated secondary operations (such as deflashing and leak testing), total output per shift is significantly elevated compared to manual or semi-automatic systems.

Furthermore, reduced downtime due to fewer manual interventions and the built-in predictive maintenance capabilities of Leshan’s equipment ensure higher machine availability and lower unplanned stoppages. This increased productivity directly translates to lower per-unit costs.

Energy Efficiency

Modern automatic EBM machines from Leshan are designed with energy conservation in mind. Innovations such as energy recovery systems, variable frequency drives, and efficient heating elements minimize energy consumption during each cycle.

Programmable logic ensures machines operate only when required, further reducing idle energy use. Over time, these features contribute to a noticeable reduction in electrical costs per unit produced.

Enhanced Quality Control and Lower Defect Rates

Incorporating vision systems and automated quality monitoring tools, Leshan’s EBM machines guarantee that each product conforms to predefined standards. Early detection of defects allows for immediate corrective action, preventing the accumulation of substandard products and reducing the financial impact of recalls and reworks.

This proactive approach not only safeguards brand reputation but also preserves resources and enhances overall production efficiency.

Comparative Cost Analysis: Traditional vs. Automatic EBM

To illustrate the cost advantages, consider the following comparison table between a traditional blow molding setup and Leshan’s automatic EBM solution:

| Cost Component | Traditional System | Leshan Automatic EBM |

|---|---|---|

| Labor | High – Multiple operators per line | Low – One operator per several lines |

| Material Waste | Moderate to High | Low (Automated control) |

| Downtime | Frequent due to manual tasks | Minimal (Automated recovery) |

| Energy Consumption | High | Optimized and lower |

| Quality Control | Manual inspection, higher rework | Automated, fewer defects |

Case Study: Leshan’s Success Stories

Case 1: Beverage Packaging Company

A major client in the beverage industry approached Leshan for a solution to reduce skyrocketing production costs. By implementing Leshan’s latest automatic EBM machines, the company achieved:

- Reduction in labor costs by 60%

- Material savings of 8% per unit

- Decrease in energy usage by 20%

- Consistent product quality with less than 1% defect rate

Case 2: Industrial Drum Manufacturer

Another case involved an industrial drum producer battling with frequent machine breakdowns and quality inconsistencies. After transitioning to Leshan’s automated solution, the manufacturer saw a significant drop in unscheduled downtime and improved batch-to-batch consistency, leading to lower overall manufacturing costs.

Return on Investment (ROI) and Payback Period

While the initial investment in an automatic EBM machine from Leshan may appear substantial, the long-term cost reductions often justify the expenditure. Savings in labor, materials, energy, and quality assurance collectively contribute to a swift return on investment.

Typically, Leshan’s clients report a payback period ranging from 12 to 24 months, after which ongoing savings continue to bolster the company’s bottom line.

Factors Influencing ROI

- Production volume

- Current operational inefficiencies

- Local labor costs

- Energy prices

- Product complexity

Scalability and Flexibility

Leshan’s automatic EBM machines are built with scalability in mind, allowing manufacturers to expand capacity or adjust product specifications with minimal disruption or added investment. Modular design, quick tooling changes, and integrated process control systems make it easy to pivot between product lines or accommodate demand fluctuations without significant downtime or retraining costs.

Sustainability and Environmental Impact

Cost savings are not the only advantage of Leshan’s advanced EBM technology. By reducing material usage, energy consumption, and waste, these machines support manufacturers in achieving environmental compliance and sustainability goals. Lower energy bills and reduced scrap rates contribute to a smaller carbon footprint, a benefit that extends beyond financial metrics.

Industry Adoption and Market Trends

As the global market becomes increasingly oriented toward automation and efficiency, more manufacturers are making the transition to automatic EBM machines. Leshan’s substantial investments in R&D, customer support, and machine customization have positioned the company as a trusted partner for manufacturers seeking to remain ahead of the curve.

Current trends indicate a growing emphasis on digitalization, data-driven manufacturing, and smart factory integration—areas where Leshan’s solutions are setting industry benchmarks.

Challenges and Considerations

Despite the clear benefits, adopting automatic EBM technology is not without its challenges. Initial capital expenditure, the need for skilled maintenance personnel, and integration with existing systems can pose hurdles. Leshan addresses these concerns through comprehensive training programs, robust after-sales support, and scalable solutions that accommodate gradual upgrades.

Manufacturers should carefully evaluate their specific needs, projected growth, and existing infrastructure before making the transition, leveraging Leshan’s consulting services for tailored recommendations.

The Leshan Difference

Leshan’s commitment to innovation, reliability, and customer satisfaction has made it a leader in the blow molding machine sector. By continuously refining its automatic EBM offerings and supporting clients at every stage of the automation journey, Leshan empowers manufacturers to achieve sustainable cost savings and operational excellence.

The company’s investment in digitalization, predictive maintenance, and machine learning integration further differentiates its equipment from competitors, ensuring that customers remain future-ready in a rapidly changing industry landscape.