Can Large Capacity EBM Machine Enhance Bottle Quality

Can Large Capacity EBM Machine Enhance Bottle Quality

Large capacity EBM (Extrusion Blow Molding) machines are revolutionizing the bottle manufacturing industry, offering unparalleled enhancements in bottle quality, production efficiency, and sustainability. Leshan, a renowned blow molding machine manufacturer, leads this transformation by delivering machines with precision engineering, advanced automation, and flexible design capabilities. These machines ensure uniform wall thickness, superior material distribution, and exceptional surface finish, all of which contribute to the production of high-quality bottles for diverse industries such as beverage, pharmaceuticals, and cosmetics. With features like real-time quality inspection, energy-efficient operation, and compatibility with recycled and bio-based materials, Leshan's EBM solutions support manufacturers in meeting stringent regulatory standards and environmental goals. Additionally, robust after-sales support and rapid mold change capabilities ensure operational reliability and agility in responding to market changes. As the industry moves towards smarter, more sustainable manufacturing, Leshan remains at the forefront, empowering clients to achieve manufacturing excellence and superior bottle quality with every production run.

For decades, the demand for high-quality plastic bottles has been increasing across industries such as food and beverage, pharmaceuticals, cosmetics, and household chemicals. As product requirements evolve and competition intensifies, manufacturers are continuously seeking innovative solutions to improve bottle quality, production efficiency, and cost-effectiveness. Enter the large capacity Extrusion Blow Molding (EBM) machine—a technology at the forefront of bottle manufacturing innovation.

As a leading blow molding machine manufacturer, Leshan has been at the heart of this technological transformation. Our expertise in designing and building advanced EBM machines enables us to deliver not only machinery but also manufacturing excellence that translates into enhanced bottle quality for our clients globally.

undefined

The Role of Large Capacity EBM Machines in Modern Bottle Manufacturing

Large capacity EBM machines represent a significant advancement in blow molding technology. With the capability to handle bigger molds, produce larger bottles, and increase throughput, these machines are essential for manufacturers aiming to meet high-volume demands without compromising on product integrity.

But can these large-scale machines truly enhance bottle quality? The answer lies in the advanced features, precise control systems, and material handling expertise embedded in Leshan’s EBM solutions. Let’s explore the core aspects that make these machines a game-changer for bottle producers.

1. Precision Engineering for Consistency

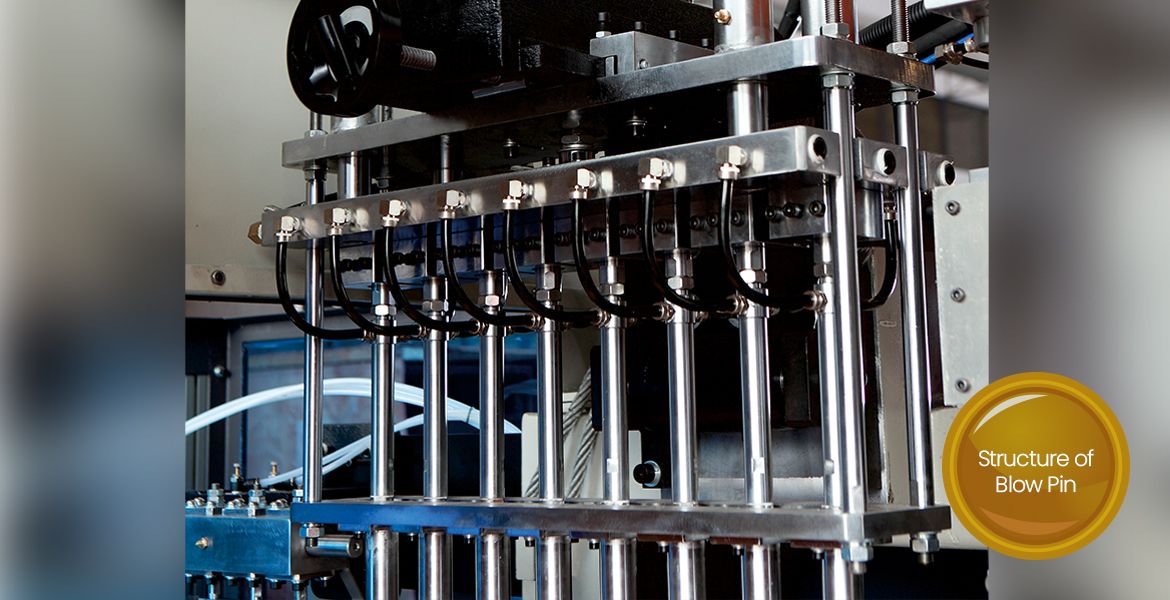

At Leshan, precision is the cornerstone of our blow molding machine manufacturing. Large capacity EBM machines are equipped with state-of-the-art control systems, servo-driven components, and high-quality molds. This ensures that each bottle produced maintains consistent wall thickness, uniform weight distribution, and superior clarity—key quality markers for any industry.

Consistency in bottle production is critical, especially when bottles are destined for markets with strict regulatory standards. Leshan’s machines use advanced monitoring sensors and real-time feedback mechanisms to detect and correct anomalies instantly, reducing wastage and delivering top-tier bottles with every cycle.

2. Enhanced Material Utilization and Strength

One of the chief concerns in bottle manufacturing is the optimal use of raw materials to achieve the perfect balance between strength and material savings. Leshan’s large capacity EBM machines feature sophisticated parison control and multilayer extrusion technology. These capabilities allow for tailored wall thickness profiles and the integration of various polymers, including recycled materials and barrier layers.

This not only improves the mechanical properties and durability of bottles but also enables the production of lightweight bottles that do not compromise on performance. By optimizing material distribution, manufacturers can ensure bottles withstand the rigors of transportation, storage, and end-use.

3. Superior Surface Finish and Aesthetic Appeal

In the competitive retail market, the appearance of packaging plays a crucial role in consumer purchasing decisions. Leshan’s EBM machines are built to deliver exceptional surface finishes, intricate designs, and a variety of textures. Thanks to precision temperature control and uniform mold cooling systems, bottles emerge from the machine with minimal defects, clear branding, and a visually appealing finish.

Customization options such as in-mold labeling, embossing, and color integration are available, allowing brand owners to differentiate their products and enhance shelf presence. These features, combined with high production speeds, give manufacturers the agility to respond to market trends without sacrificing quality.

4. Advanced Automation for Quality Assurance

Automation is the backbone of modern manufacturing, and Leshan integrates the latest automation technologies into its large capacity EBM machines. Automated quality control systems, including vision inspection, leak testing, and online measurement, ensure that defects are detected and rectified before bottles reach packaging or dispatch.

This level of automation not only reduces human error and labor costs but also enables data-driven decision-making. By harnessing production analytics, manufacturers can identify trends, optimize processes, and maintain consistent quality standards across large production runs.

5. Energy Efficiency and Sustainability

With rising environmental awareness and tightening regulations, sustainability has become a key focus for bottle manufacturers. Leshan’s EBM machines are engineered for energy efficiency, utilizing servo motors, low-energy heaters, and closed-loop cooling systems. These features lower the carbon footprint of production and contribute to cost savings.

In addition, the flexibility to process bio-based plastics and recycled materials positions Leshan’s large capacity EBM machines as a sustainable solution for forward-thinking manufacturers. Our commitment to green manufacturing helps clients align with global trends while maintaining the highest standards of bottle quality.

6. Flexibility for Diverse Bottle Designs

Market demands are continuously evolving, with brands seeking unique shapes, sizes, and functionalities for their bottles. Leshan’s large capacity EBM machines are designed for versatility. Quick-change mold systems, multi-cavity capability, and adjustable process parameters enable seamless transitions between different bottle designs and production requirements.

This flexibility empowers manufacturers to efficiently produce a wide range of bottles—from large containers for industrial use to small, intricate bottles for cosmetics—without lengthy downtimes or excessive costs. The ability to adapt quickly to new product launches or seasonal packaging changes is a valuable competitive advantage.

7. Robust Machine Reliability and After-Sales Support

Machine uptime directly impacts productivity and, ultimately, profitability. Leshan’s large capacity EBM machines are built for durability, with high-quality components, robust frames, and reliable hydraulic and pneumatic systems. Our comprehensive after-sales support, including training, spare parts supply, and remote diagnostics, ensures that clients can maintain continuous production and consistent bottle quality.

Regular maintenance programs and proactive customer service further reduce the risk of unexpected downtime, making Leshan a trusted partner for long-term manufacturing success.

Comparative Table: Key Advantages of Leshan Large Capacity EBM Machines

| Feature | Benefit to Bottle Quality |

|---|---|

| Precision Parison Control | Uniform wall thickness, improved strength, reduced defects |

| Multilayer Extrusion | Enhanced barrier properties, use of recycled materials |

| Automated Quality Inspection | Early defect detection, consistent quality |

| Advanced Cooling Systems | Superior surface finish, reduced cycle time |

| Flexible Mold Change | Adaptability to diverse bottle designs and market needs |

| Energy Efficient Design | Lower production costs, sustainable operations |

Why Choose Leshan as Your Blow Molding Machine Manufacturer?

Leshan is not just a machinery supplier; we are a strategic partner in your manufacturing journey. Our team of experts works closely with clients to assess production needs, recommend optimal machine configurations, and provide end-to-end support from installation to daily operation. With a deep understanding of global quality standards and industry best practices, Leshan ensures that every large capacity EBM machine delivers value, reliability, and superior bottle quality.

Real-World Case Studies: Leshan EBM Machines in Action

- Beverage Industry: A major beverage bottler adopted Leshan’s large capacity EBM machine, achieving a 30% improvement in bottle weight consistency and substantial reduction in production rejects.

- Pharmaceutical Packaging: Leshan’s automated quality assurance features enabled a pharmaceutical client to meet stringent FDA and EU standards for packaging integrity and cleanliness.

- Cosmetics Packaging: With rapid mold change and intricate design capabilities, a cosmetics manufacturer expanded its product lines without sacrificing quality or time-to-market.

These success stories underscore the transformative impact of investing in advanced blow molding solutions from Leshan.

Future Trends: The Evolution of EBM Technology

The future of bottle manufacturing lies in continued innovation. Leshan is at the forefront, investing in research and development to push the boundaries of EBM technology. Anticipated advancements include smart manufacturing integration, IoT-enabled monitoring, AI-driven predictive maintenance, and greater use of sustainable materials.

Manufacturers partnering with Leshan can expect to stay ahead of market trends, benefiting from both enhanced bottle quality and operational efficiency. Our vision is to empower clients to meet tomorrow’s challenges with confidence and creativity.

Partner with Leshan, and experience the difference a world-class blow molding machine manufacturer can make in your bottle production journey.