Can Upgrading Your Industrial Blow Molding Machine Save Costs

Can Upgrading Your Industrial Blow Molding Machine Save Costs

Upgrading industrial blow molding machines offers substantial cost-saving opportunities for manufacturers. As a leading blow molding machine manufacturer, Leshan has observed that modern machines dramatically outperform legacy equipment in several key areas. The primary benefits include reduced energy consumption, minimized material waste, lower maintenance and repair expenses, faster production cycles, and improved product quality. These improvements are made possible through technological advancements such as servo motors, automated process control, efficient heating systems, and predictive maintenance capabilities. Real-world case studies from Leshan clients demonstrate energy savings of up to 40%, reduced material scrap, increased throughput, and significant decreases in labor and downtime costs. Additionally, upgraded machines help companies achieve sustainability targets, reduce their environmental impact, and enhance brand reputation. When planning an upgrade, it is crucial to evaluate production needs, ROI, integration with existing systems, and proper staff training. Ultimately, manufacturers who partner with Leshan for equipment upgrades can achieve recurring operational savings, improved efficiency, and future-proof their production lines against rising costs and evolving market demands.

Industrial blow molding is a cornerstone process for manufacturing plastic containers, automotive parts, and numerous other critical components. As a leading blow molding machine manufacturer, Leshan has continuously observed the evolution of this technology and how it shapes the cost structure for factories worldwide. In today’s competitive industrial landscape, manufacturers are constantly seeking ways to lower operational costs while maximizing productivity and maintaining high output quality. One of the most effective strategies is upgrading your industrial blow molding machine. But how exactly does this translate to cost savings?

The Current Landscape of Industrial Blow Molding

Before delving into cost-saving mechanisms, it is important to understand the current environment. Leshan, with decades of experience in blow molding machine manufacturing, has witnessed a significant transformation in both machine efficiency and process automation. Many factories are still operating legacy machines that, while robust, may not utilize the latest technological advances. These older models often consume more energy, require frequent maintenance, and may not integrate smoothly with modern digital systems. The result: higher operational costs, increased downtime, and potential quality inconsistencies.

Key Cost Factors in Blow Molding Operations

Identifying the main contributors to operational costs is crucial. At Leshan, we have categorized cost factors as follows:

- Energy Consumption: The energy required to heat, shape, and cool plastics is considerable. Older machines are typically less energy efficient.

- Material Wastage: Outdated machines may not optimize material usage, leading to more scrap and higher raw material costs.

- Maintenance & Repairs: Mechanical wear and obsolete components can lead to frequent stoppages and expensive repairs.

- Labor: Manual adjustments and interventions often increase with older equipment, requiring more skilled operators.

- Downtime: Machine breakdowns and slow changeovers reduce overall productivity and lead to lost income opportunities.

Technological Advancements in Blow Molding Machines

Leshan has continually invested in research and development to address these cost factors. Modern blow molding machines present several technological improvements:

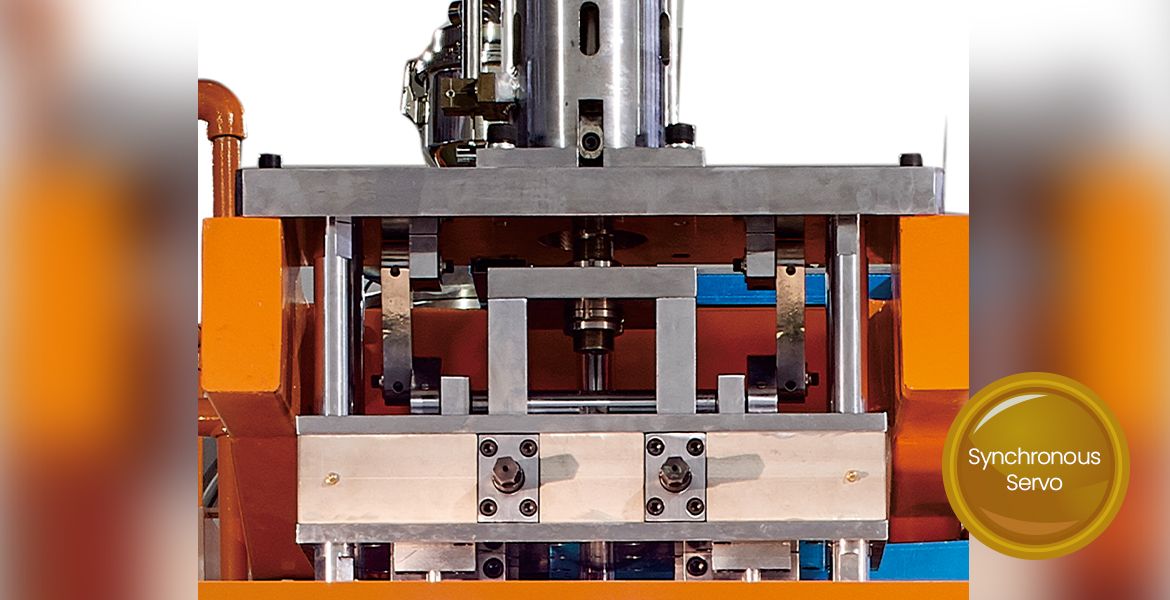

- Servo Motor Technologies: These enable precise control of parison and clamping, reducing cycle times and energy usage.

- Automated Process Control: Integration of PLCs (Programmable Logic Controllers) and IoT-ready interfaces allows for real-time monitoring and adjustment, minimizing defects and material waste.

- Efficient Heating Systems: Advanced infrared and induction heating systems reduce heating times and lower energy consumption.

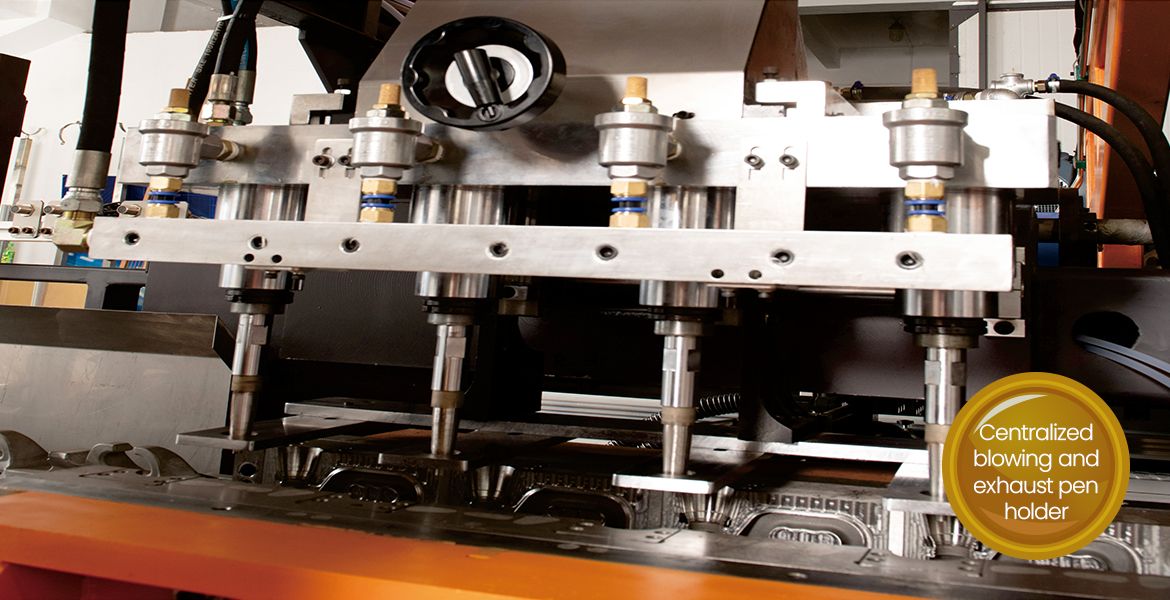

- Enhanced Mold Design: Updated mold cooling and venting features enable faster cycles and improved product consistency.

- Predictive Maintenance: Sensors and software can predict component wear, reducing unplanned downtime and repair costs.

Cost-Saving Benefits of Upgrading Your Blow Molding Machine

From Leshan’s extensive field data and customer feedback, the following cost-saving benefits emerge for factories that upgrade their blow molding equipment:

1. Reduced Energy Bills

Modern machines built by Leshan are equipped with variable frequency drives and optimized heating systems. These features ensure that only the necessary amount of energy is used at any given moment, resulting in significant savings. Reports from Leshan clients indicate energy cost reductions ranging from 15% to 40% after upgrading.

2. Less Material Waste

Precise parison control and improved mold alignment lead to fewer rejects and less scrap. Leshan’s machines incorporate automatic thickness control, which minimizes excess material use. This not only reduces raw material expenses but also lowers the costs associated with waste management and environmental compliance.

3. Lower Maintenance and Repair Costs

With modular designs, self-diagnostic systems, and predictive maintenance features, the frequency and severity of breakdowns are greatly reduced. Leshan’s new-generation blow molding machines use high-grade, wear-resistant parts, which last longer and are easier to replace. This translates into lower spare parts inventory and decreased labor costs associated with repairs.

4. Faster Production Cycles

Upgraded machines can dramatically shorten cycle times through better cooling, optimized mold motion, and enhanced process control. For example, Leshan’s high-speed blow molding line can increase output by up to 30% over legacy machinery. This means more products in less time, maximizing revenue potential while keeping fixed costs stable.

5. Automation and Staffing Efficiency

Automation features in Leshan’s latest machines reduce the need for manual intervention. Fewer operators are required for each production line, and the skill level required for operation may decrease as well, freeing highly skilled personnel for more value-added tasks. This can result in both direct labor savings and improved employee satisfaction due to fewer repetitive, high-stress tasks.

6. Improved Product Quality and Reduced Returns

Better process control and consistency mean fewer defective products reaching the market. Leshan customers have noted a measurable reduction in customer complaints and returns after upgrading, which translates into lower warranty costs and improved brand reputation.

Cost Analysis: Upgrading vs. Maintaining Legacy Equipment

When evaluating the potential for cost savings, companies must balance the upfront investment of upgrading against the recurring costs of maintaining older equipment. Leshan’s financial analysis for its customers often includes the following comparative table:

| Cost Factor | Legacy Machine | Leshan Modern Machine |

|---|---|---|

| Annual Energy Cost | High | Reduced by 15-40% |

| Material Waste | Moderate to High | Minimal |

| Repair Frequency | Frequent | Rare with Predictive Maintenance |

| Downtime | Multiple Hours/Week | Minimal |

| Labor Costs | High (more operators) | Lower (automation) |

| Output/Throughput | Limited | 30%+ Increase |

As seen above, the cumulative impact of operating a modern Leshan blow molding machine can quickly outweigh the initial upgrade expenses, especially as energy and labor costs continue to rise globally.

Case Studies: Real-World Results from Leshan Clients

Case Study 1: Food Packaging Manufacturer

A medium-sized food packaging company replaced its decade-old blow molding equipment with a new Leshan servo-driven machine. Post-upgrade data showed:

- 28% reduction in total energy consumption

- 20% decrease in material waste

- 30% increase in production throughput

- Machine downtime cut by 85%

Case Study 2: Automotive Components Supplier

An automotive supplier upgraded its legacy machines to Leshan’s automated, PLC-controlled models. The result:

- Annual maintenance costs fell by 50%

- Labor needs decreased by 2 operators per shift

- Product rejection rates dropped from 4% to less than 1%

Case Study 3: Chemical Drum Producer

A high-volume chemical drum producer adopted Leshan’s high-capacity, multi-layer blow molding system. The improvements included:

- Raw material savings of up to 18% thanks to superior parison control

- Faster changeovers, reducing downtime by 70%

- Fewer customer claims due to improved product consistency

Additional Advantages: Sustainability and ESG Goals

Modernizing your blow molding machine fleet with Leshan equipment also aligns with growing environmental, social, and governance (ESG) requirements. Energy-efficient machines help reduce the plant’s carbon footprint. Lower material waste and improved recyclability of process scrap further contribute to sustainability goals. Many of Leshan’s customers have leveraged these improvements to attain green certifications and satisfy regulatory requirements, indirectly saving on compliance and marketing costs.

Considerations When Planning an Upgrade

Deciding to upgrade is a significant step. Leshan recommends that manufacturers consider the following when planning:

- Production Needs: Analyze current and future throughput requirements, product range, and customization needs.

- Return on Investment (ROI): Calculate projected cost savings against capital outlay, factoring in all operational improvements.

- Integration: Assess how new machines will interact with existing systems such as ERP, MES, and quality control platforms.

- Training: Plan for operator and maintenance staff training to fully leverage new features.

- Scalability: Ensure the upgrade pathway supports future process expansion or new product development.

Leshan’s Commitment to Continuous Improvement

At Leshan, our philosophy is to empower manufacturers with technology that delivers not just immediate cost savings, but also long-term competitive advantage. Our modular machine designs, robust support services, and commitment to innovation ensure that customers can confidently upgrade their blow molding operations without disruption. Whether for small batch manufacturers or high-volume industrial giants, we tailor solutions that fit each client’s unique requirements, ensuring operational efficiency and bottom-line improvement.

Summary Table: Core Cost Savings by Upgrading with Leshan

| Area | Legacy Machine Issue | Leshan Upgrade Benefit |

|---|---|---|

| Energy | High usage | 15-40% savings |

| Material | Excessive waste | Optimized consumption |

| Maintenance | Frequent repairs | Predictive, less frequent |

| Labor | Manual, intensive | Automated, efficient |

| Downtime | Common | Rare |

| Quality | Inconsistency | Stable, high |

The Path Forward

In summary, the case for upgrading your industrial blow molding machine is compelling, especially when partnering with an experienced manufacturer like Leshan. As energy, labor, and material costs continue to climb, the relative benefits of modern machinery will only increase. Savvy manufacturers are already realizing significant savings, operational resilience, and enhanced product quality by investing in advanced blow molding technology. With careful planning and the right partner, your factory can unlock substantial, recurring cost reductions and position itself for long-term success.