Does a PET Blow Molding Machine with Precision Control Deliver Better Bottle Quality

Does a PET Blow Molding Machine with Precision Control Deliver Better Bottle Quality

Precision control in PET blow molding machines is transforming bottle manufacturing, and Leshan, a leading blow molding machine manufacturer, is at the forefront of this evolution. By integrating advanced control systems—such as multi-point temperature sensors, servo-driven stretch rods, and real-time quality monitoring—Leshan ensures every stage of the production process operates under optimal conditions. This results in bottles with uniform wall thickness, enhanced clarity, and superior structural integrity. Manufacturers benefit from reduced defect rates, the ability to lightweight bottles, and increased operational efficiency. Customer experiences confirm significant improvements in product quality and productivity after transitioning to Leshan's precision-controlled machines. Looking ahead, Leshan continues to innovate with Industry 4.0 technologies, promising even tighter control and smarter manufacturing. For brands seeking consistent, high-quality PET bottles, partnering with Leshan offers a clear pathway to success.

Introduction to Leshan and PET Blow Molding Technology

As a reputable blow molding machine manufacturer, Leshan has consistently pushed the boundaries of technology in plastic bottle manufacturing. PET (Polyethylene Terephthalate) bottles are widely used across industries, from beverages to pharmaceuticals, owing to their transparency, durability, and recyclability. At the heart of PET bottle manufacturing lies the blow molding process, and precision control in these machines plays a pivotal role in determining product quality.

In today's competitive market, brands demand more than just quantity—they seek reliability, aesthetic appeal, and consistent performance in every bottle produced. Leshan's innovative approach in integrating precision control systems into PET blow molding machines has set new benchmarks in bottle quality.

Understanding PET Blow Molding and Its Challenges

The PET blow molding process involves stretching and blowing a heated PET preform into a mold cavity to form a bottle. This process, while simple in theory, is highly sensitive to variables such as temperature, air pressure, and preform consistency. Even minor fluctuations can lead to defects such as uneven wall thickness, poor clarity, or structural weaknesses.

Manufacturers like Leshan recognize that overcoming these challenges requires more than just robust machinery—it demands machines equipped with advanced control systems that can monitor and adjust key parameters in real time. This is where precision control in blow molding machines becomes essential.

undefined

Precision Control: What Does It Mean?

Precision control refers to the ability of a blow molding machine to monitor and adjust process parameters with high accuracy and repeatability. In Leshan's PET blow molding machines, precision control encompasses:

- Accurate temperature regulation of the preform and mold

- Stable and precise air pressure delivery

- Consistent stretch rod movement and synchronization

- Real-time feedback and correction for process deviations

By leveraging cutting-edge sensors, automation, and intelligent software, Leshan ensures that each stage of the blow molding process is executed under optimal conditions. The result? Superior bottle quality, reduced wastage, and higher productivity.

How Precision Control Translates Into Better Bottle Quality

1. Uniform Wall Thickness

One of the most critical aspects of PET bottle quality is achieving uniform wall thickness. Inconsistent thickness can lead to weak spots, uneven weight distribution, and bottle deformation. Leshan's precision-controlled blow molding machines ensure that temperature and stretching forces are meticulously balanced, resulting in bottles with consistent walls throughout.

2. Enhanced Clarity and Aesthetics

Clarity is a key selling point for PET bottles, particularly in beverage and cosmetic industries. Precision control allows Leshan machines to maintain optimal processing temperatures, which reduces crystallization and surface defects. The outcome is crystal-clear bottles that enhance product appeal on the shelf.

3. Structural Integrity and Durability

Bottle strength must meet rigorous standards to withstand transportation and storage. By precisely controlling air pressure and mold conditions, Leshan's machines produce bottles with excellent mechanical properties, minimizing the risk of splitting or collapsing.

4. Lightweighting Opportunities

With precision control, manufacturers can confidently reduce the amount of PET used per bottle without compromising quality. Leshan's machines enable lightweighting by ensuring that even thinner bottles maintain their strength and functionality, contributing to sustainability and cost savings.

Features of Leshan’s Precision-Controlled PET Blow Molding Machines

Leshan integrates a range of advanced features into its PET blow molding machines to maximize precision and efficiency.

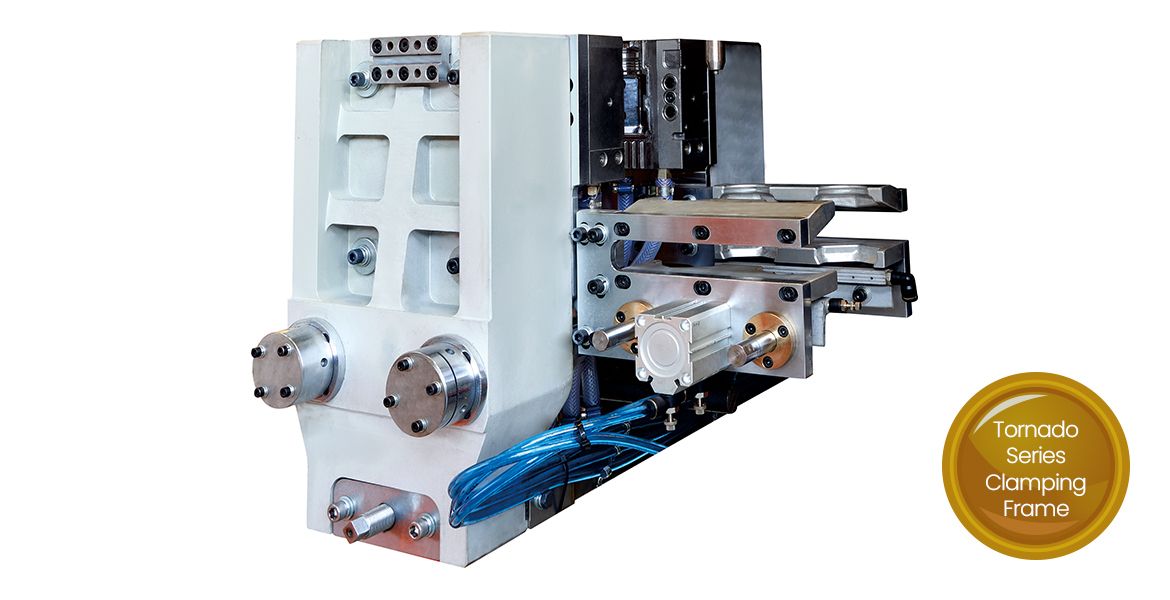

- Advanced PLC Control Systems: Leshan uses programmable logic controllers (PLCs) to automate and synchronize the entire production cycle. This guarantees accuracy and repeatability.

- Multi-point Temperature Sensors: These monitor and adjust the heat profile across the preform and mold for optimal material flow and clarity.

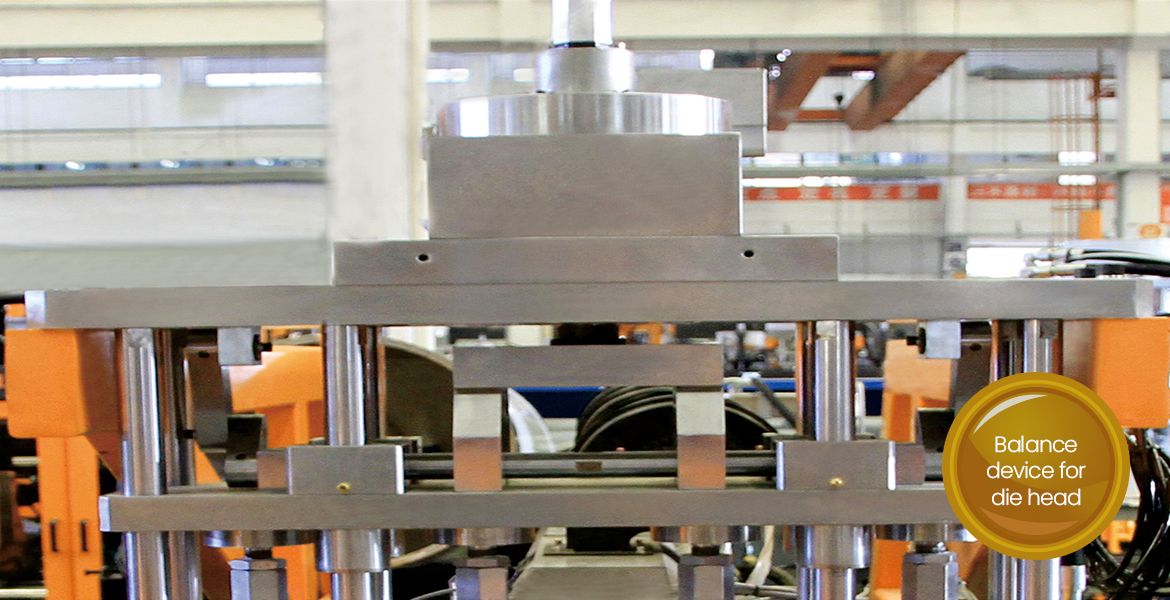

- Servo-driven Stretch Rods: Servo motors provide precise control over the stretching process, ensuring consistent bottle dimensions and mechanical properties.

- Real-Time Quality Monitoring: Integrated cameras and sensors detect anomalies instantly, allowing for immediate corrections and reduced defect rates.

- User-Friendly HMI Panels: Operators can easily monitor, adjust, and store machine settings for different bottle types, minimizing human error and setup times.

These features combine to deliver a solution that not only produces better bottles but also simplifies operation and enhances overall factory productivity.

The Impact of Precision Control on Production Efficiency

In addition to improving bottle quality, precision control systems from Leshan lead to substantial gains in production efficiency. Machines operate faster, with fewer stoppages for manual adjustments or quality checks. Scrap rates decrease, and consistency across production batches improves, making it easier for manufacturers to fulfill large orders with confidence.

Furthermore, the ability to monitor and record process data provides valuable insights for continuous process improvement and predictive maintenance. This holistic approach to quality and efficiency cements Leshan's reputation as a trusted blow molding machine manufacturer.

Customer Experiences: Case Studies from Leshan Clients

Many of Leshan's clients have seen firsthand how precision control technology has transformed their operations. Some report up to a 25% reduction in defect rates and significant improvements in bottle clarity and shelf appeal. Others highlight the ease of switching between bottle designs and the reliable performance that allows them to meet tight production schedules without compromising quality.

The trust placed in Leshan's solutions is demonstrated by the growing number of repeat customers and industry accolades received for innovation and performance.

Future Trends: Smart Manufacturing and Digital Integration

As Industry 4.0 continues to reshape manufacturing, Leshan is at the forefront of integrating digital technologies into its PET blow molding machines. IoT connectivity, cloud-based process monitoring, and AI-driven optimization are all on the horizon, promising even greater precision and control for future generations of bottle manufacturing equipment.

In this era of smart manufacturing, precision control will play an even more central role in delivering consistent, high-quality PET bottles while reducing environmental impact and operational costs.

Summary Table: Precision Control Benefits in PET Blow Molding

| Aspect | Traditional Machines | Leshan Precision-Controlled Machines |

|---|---|---|

| Wall Thickness Uniformity | Variable | Consistent & Precise |

| Defect Rate | Higher | Significantly Lower |

| Clarity | Occasional Haze | Crystal Clear |

| Production Speed | Moderate | High & Stable |

| Flexibility | Manual Adjustments Required | Easy Switch via HMI |

Final Thoughts on Leshan’s Role in Advancing Bottle Quality

Leshan’s commitment to innovation in blow molding machine manufacturing continues to shape the future of PET bottle production. By embracing precision control and smart manufacturing, Leshan empowers its customers to achieve new levels of quality and efficiency in their operations. As the demand for high-performance, eco-friendly PET bottles grows, the advantages of partnering with a leader like Leshan become increasingly clear.

Tags:automatic blow molding machine,EBM blow molding machine supplier