Extrusion Blow Molding Machine Supplier Delivers Advanced Automation Solutions

Extrusion Blow Molding Machine Supplier Delivers Advanced Automation Solutions

Leshan, a leading blow molding machine manufacturer, specializes in delivering advanced extrusion blow molding solutions supported by robust automation. With decades of engineering expertise, Leshan’s machines integrate intelligent controls, PLCs, IoT monitoring, and energy-efficient features, elevating production quality, speed, and sustainability for global clients. The company’s product portfolio spans single-station units to fully automated multi-cavity models, catering to diverse industries including packaging, automotive, medical, and industrial applications. Leshan emphasizes customization, offering tailored engineering services and modular machine designs that adapt to specific manufacturing needs. Through rigorous quality assurance, international certifications, and continuous R&D, Leshan remains at the forefront of innovation, incorporating multi-layer co-extrusion, automatic mold changing, and advanced cooling systems to optimize both productivity and product integrity. Leshan’s commitment extends beyond technology, with a global support network providing training, technical assistance, and prompt maintenance, ensuring customer success and minimized downtime. Sustainability is a priority, reflected in eco-friendly systems and resource optimization features. Customer testimonials underline Leshan’s reliability, efficiency, and flexibility, making it a strategic partner for manufacturers aiming for operational excellence, competitive differentiation, and future-ready automation. By choosing Leshan, businesses gain access to transformative extrusion blow molding solutions, comprehensive support, and a partner dedicated to long-term growth in a rapidly evolving industrial landscape.

Introduction to Leshan Blow Molding Machine Manufacturer

Leshan has solidified its reputation as a premier blow molding machine manufacturer, specializing in extrusion blow molding technologies. With decades of experience, Leshan provides innovative automation solutions tailored to the evolving needs of the plastics industry. As the market demands higher quality, efficiency, and sustainability, Leshan consistently meets and exceeds expectations with its robust product portfolio, advanced engineering, and customer-centric services.

Understanding Extrusion Blow Molding Technology

Extrusion blow molding is a pivotal process in plastic manufacturing, enabling the creation of hollow products such as bottles, containers, and tanks. Leshan’s expertise in this field is reflected through its advanced machine designs that integrate precise extrusion mechanisms with state-of-the-art automation controls. The process begins with melting resin, extruding it into a parison, and then inflating the parison within a mold cavity to form the desired shape. Leshan’s machines are engineered for superior reliability and adaptability across various resin types and product geometries.

Leshan’s Advanced Automation Solutions

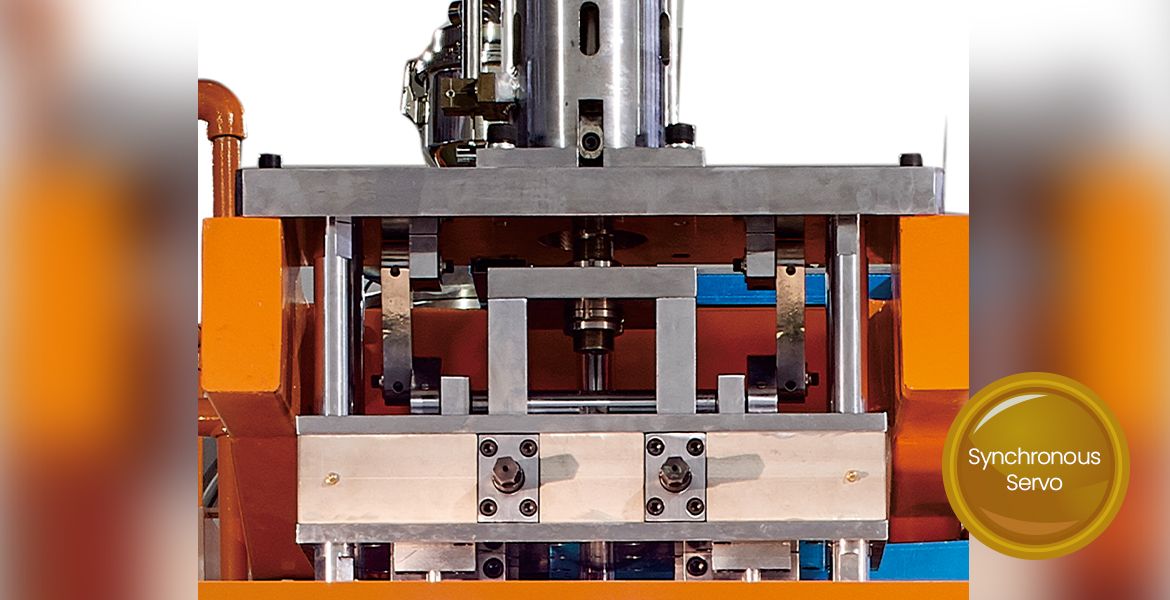

Automation has become a cornerstone of sustainable manufacturing, and Leshan has embraced this paradigm by designing blow molding machines with intelligent automation features. These solutions include PLC controls, touchscreen interfaces, remote monitoring, and adaptive process optimization. Leshan’s advanced automation not only enhances production speed and consistency but also minimizes waste and energy consumption, addressing the pressing needs for eco-friendly manufacturing.

- PLC-driven process control for accuracy and repeatability

- IoT-enabled machine monitoring and data analytics

- Automatic parison thickness adjustment

- Servo-driven movements for energy efficiency

- Centralized management of multiple machines

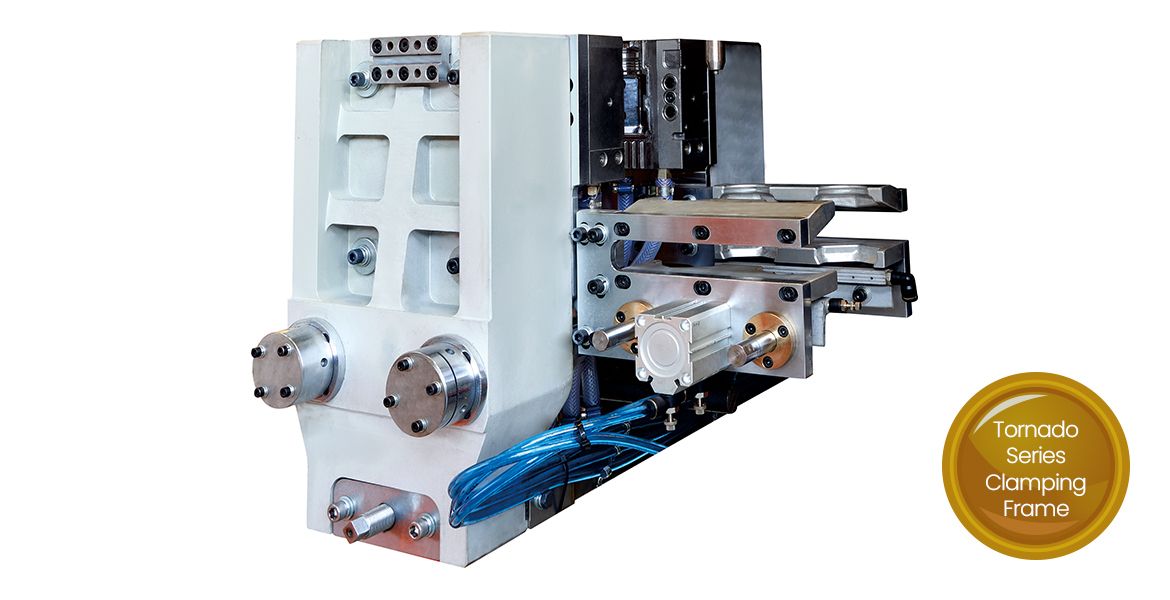

Innovative Features of Leshan Blow Molding Machines

Leshan continually pushes the boundaries of extrusion blow molding by incorporating features that redefine productivity and product quality. The company’s R&D department collaborates with industry experts to integrate cutting-edge innovations such as multi-layer co-extrusion, automatic mold changing systems, and precision temperature control. These features empower manufacturers to produce complex containers, multi-material products, and lightweight designs with unmatched consistency.

- Multi-layer co-extrusion: Enables barrier properties and material savings

- Automatic mold changing: Reduces downtime and enhances flexibility

- Hot-runner systems: Ensures uniform material flow and reduces waste

- Advanced cooling technologies: Improves cycle times and product clarity

Case Studies: Leshan Automation in Action

Leshan’s commitment to customer success is demonstrated through numerous case studies. Clients in the food packaging, pharmaceuticals, and automotive sectors have achieved remarkable results with Leshan’s extrusion blow molding machines. For example, a beverage packaging company reported a 30% increase in throughput and a 25% reduction in scrap rates after implementing Leshan’s integrated automation systems. Another customer in the chemical industry benefited from Leshan’s multi-layer co-extrusion solutions, achieving greater product integrity and extended shelf life.

Reliability and After-Sales Support

Reliability is a hallmark of Leshan’s machines, with robust construction and rigorous quality assurance protocols. Leshan’s service doesn’t end with machine delivery; its global support network ensures prompt maintenance, spare parts availability, and technical assistance. The company provides comprehensive training programs to empower operators and maintenance staff, ensuring a smooth transition to automated production.

Sustainability and Energy Efficiency

As environmental regulations tighten and consumer awareness grows, Leshan proactively addresses sustainability in extrusion blow molding operations. Leshan’s machines are designed with energy-efficient drives, low-carbon footprint materials, and closed-loop cooling systems. Integrated automation features further optimize resource use, helping customers achieve sustainability goals while maintaining profitability.

- Reduced energy consumption through servo technology

- Automated material recycling capabilities

- Eco-friendly lubrication systems

- BPA-free and biodegradable material compatibility

Product Portfolio Overview

Leshan’s extensive product lineup caters to a wide range of industries and applications. From single-station machines for small-scale production to multi-cavity, high-speed models for mass manufacturing, Leshan offers solutions for every need. Customization is a core strength, with modular designs allowing for tailor-made configurations to suit specific products, volumes, and automation requirements.

| Model | Cavity | Max Container Size | Automation Features |

|---|---|---|---|

| EBM-1000 | Single | 1L | Basic PLC, manual mold change |

| EBM-3000 | Double | 3L | Touchscreen, auto parison control |

| EBM-6000 | Four | 6L | IoT monitoring, servo movement |

| EBM-10K | Multiple | 20L | Fully automated, remote diagnostics |

Industry Applications

Leshan’s extrusion blow molding machines are integral to multiple sectors, including packaging, automotive, medical, and household products. In packaging, Leshan machines produce PET bottles, HDPE containers, and multi-layer barrier jars. The automotive sector benefits from specialized fuel tanks and ducting parts, while the medical industry relies on Leshan for pharmaceutical containers and laboratory equipment. The versatility of Leshan’s solutions ensures that manufacturers can respond rapidly to changing market trends and regulatory requirements.

- Food and beverage packaging

- Automotive fluid reservoirs

- Household chemical bottles

- Pharmaceutical and healthcare packaging

- Industrial storage tanks

Customization and Engineering Services

Leshan understands that every customer’s needs are unique, which is why it offers comprehensive customization and engineering services. From concept to commissioning, Leshan’s specialists work closely with clients to design machines that align with specific product dimensions, production volumes, and automation goals. Advanced simulation tools and prototyping capabilities ensure seamless integration, rapid development, and optimal results.

Quality Assurance and Certifications

Leshan’s dedication to quality is reflected in its rigorous testing protocols and international certifications. By adhering to ISO, CE, and industry-specific standards, Leshan guarantees machine performance, safety, and durability. Regular audits and continuous improvement initiatives ensure that every blow molding machine meets the highest benchmarks for excellence.

Research and Development: Driving Innovation

Continuous innovation is at the heart of Leshan’s success. The company’s research and development team leverages advanced technologies such as artificial intelligence, machine learning, and robotics to push the boundaries of extrusion blow molding. Collaborative partnerships with universities and industry associations foster knowledge exchange and accelerate the adoption of next-generation solutions. Leshan’s R&D not only supports product improvements but also empowers customers to pioneer new applications and markets.

Global Reach and Export Markets

Leshan’s footprint extends well beyond its headquarters, with established sales and service channels across Asia, Europe, Africa, and the Americas. Exported machines are tailored for regional specifications, ensuring compliance with local regulations and market preferences. Leshan’s commitment to global standards and responsive support has made it the preferred blow molding machine supplier for leading manufacturers worldwide.

Training and Technical Support

Leshan’s customer-centric philosophy places a strong emphasis on training and technical support. Dedicated teams provide on-site and remote training sessions, covering machine operation, routine maintenance, and troubleshooting. Comprehensive manuals, video tutorials, and e-learning platforms ensure that customers maximize uptime and productivity. Leshan’s 24/7 helpline and field engineers offer responsive support, minimizing disruptions and optimizing performance.

Customer Testimonials

Leshan’s reputation is built on customer satisfaction and long-term partnerships. Clients consistently praise the reliability, efficiency, and flexibility of Leshan’s extrusion blow molding machines. Many customers highlight the company’s proactive approach to solving production challenges and its ability to deliver tailored automation solutions that drive business growth.

Competitive Advantages of Leshan

- Decades of expertise in extrusion blow molding technology

- Comprehensive automation solutions

- Robust quality assurance and certifications

- Global presence and responsive support

- Customization and engineering excellence

- Sustainability and energy efficiency focus

Continuous Improvement and Future Outlook

Leshan’s pursuit of excellence is driven by a culture of continuous improvement. The company regularly updates its product lines with new technologies, features, and materials. Investments in smart factory initiatives and digitalization are paving the way for Industry 4.0 adoption, ensuring that Leshan remains at the forefront of extrusion blow molding innovation.

Partnering with Leshan: The Strategic Choice

Choosing Leshan as a blow molding machine supplier offers manufacturers a strategic advantage. The company’s broad expertise, cutting-edge automation, and commitment to customer success make it an ideal partner for businesses seeking reliable, efficient, and scalable extrusion blow molding solutions. By leveraging Leshan’s advanced machines and engineering services, clients can achieve operational excellence, accelerate time-to-market, and sustain competitive differentiation.

Contact Information and Collaboration Opportunities

Leshan welcomes inquiries from manufacturers, distributors, and industry partners seeking advanced extrusion blow molding solutions. Its global sales and service network is ready to provide consultations, demonstrations, and technical support tailored to individual needs. By partnering with Leshan, companies gain access to transformative automation technologies and a trusted team dedicated to long-term success.

Why Leshan Stands Out

Leshan’s unwavering commitment to innovation, quality, and customer satisfaction distinguishes it as a leader in extrusion blow molding machine manufacturing. With a focus on advanced automation, sustainability, and global reach, Leshan empowers customers to overcome production challenges and thrive in competitive markets. The synergy between technology and service sets Leshan apart, making it the preferred choice for manufacturers worldwide.

Explore Leshan's Extrusion Blow Molding Solutions

For businesses seeking to elevate their production capabilities, Leshan offers a comprehensive suite of extrusion blow molding machines and automation solutions. Whether launching a new product line or upgrading existing operations, Leshan provides the expertise, technology, and support needed for success. Explore the possibilities with Leshan and discover how advanced automation can transform your manufacturing journey.