HDPE Bottle Blow Molding Machine ODM Design Innovations for Your Business

HDPE Bottle Blow Molding Machine ODM Design Innovations for Your Business

Leshan, a renowned blow molding machine manufacturer, leads the market in innovative HDPE bottle blow molding machine ODM (Original Design Manufacturing) solutions. By offering tailored machines for unique bottle designs and production requirements, Leshan enables businesses to enhance efficiency, product quality, and scalability. Key ODM innovations include multi-layer extrusion technology, energy-efficient heating, advanced automation and robotics, smart digital controls, and ergonomic user-centric designs. These advancements allow manufacturers to produce high-quality bottles with specialized properties while reducing operational costs and improving sustainability. Leshan’s collaborative ODM process covers every stage from concept analysis to commissioning, ensuring each solution is custom-engineered and seamlessly integrated. Case studies illustrate the successful deployment of Leshan machines in sectors such as pharmaceuticals and beverages, highlighting benefits like regulatory compliance, rapid prototyping, and increased output. As the packaging industry evolves, Leshan continues to drive trends in recyclability, lightweighting, and digital manufacturing, making it the partner of choice for forward-thinking companies seeking competitive advantage in HDPE bottle production.

In today’s fast-paced manufacturing sector, staying ahead requires both technological advancement and customized solutions. Leshan, a leading blow molding machine manufacturer, pioneers the development of innovative HDPE bottle blow molding machine designs through its dedicated Original Design Manufacturing (ODM) services. As businesses strive for greater efficiency, product quality, and competitive differentiation, Leshan’s commitment to engineering excellence and tailored manufacturing provides an unmatched advantage for enterprises across the plastics industry.

About Leshan: Pioneering Blow Molding Machine Manufacturer

For decades, Leshan has been at the forefront of blow molding technology. Specializing in HDPE bottle blow molding machines, the company distinguishes itself through an unwavering focus on quality, reliability, and innovation. Leshan’s state-of-the-art production facilities and specialized R&D teams have enabled the company to deliver a diverse range of machinery, adaptable to the evolving needs of businesses worldwide.

Understanding ODM in Blow Molding Machinery

Original Design Manufacturing (ODM) is a powerful approach, granting clients access to proprietary machine designs tailored to unique product requirements. Leshan’s ODM services not only provide fully customized HDPE blow molding machines but also back these solutions with extensive technical support and aftersales service. By leveraging ODM, businesses can introduce innovative bottle designs, improve production efficiency, and scale operations with confidence.

Key Advantages of Leshan’s ODM Blow Molding Services

- Customization: Machines engineered to precise specifications, including bottle shapes, sizes, and output rates.

- Innovation: Access to cutting-edge features, energy-saving systems, and automation options.

- Reliability: Robust machines built with premium materials for long-life production cycles.

- Scalability: Solutions ranging from pilot projects to full-scale mass production lines.

- Comprehensive Support: From design consultation to installation, training, and maintenance.

Innovations in hdpe blow molding machine Design

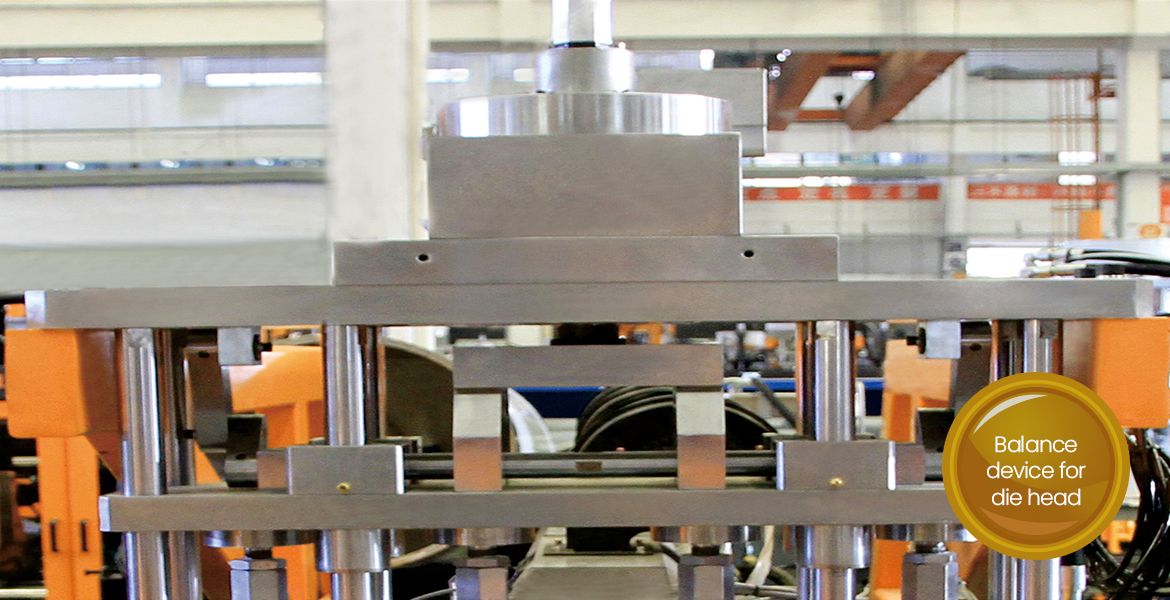

Leshan’s engineering team continually explores new possibilities in blow molding technology. Their ODM design innovations focus on increasing efficiency, flexibility, and sustainability for HDPE bottle production. Here are some of the latest advancements:

1. Multi-Layer Extrusion Technology

Leshan’s multi-layer extrusion systems allow manufacturers to produce HDPE bottles with specialized barrier properties or unique visual effects. This capability enhances product shelf-life and branding, opening doors to new markets such as food & beverage, pharmaceuticals, and agrochemicals.

2. Energy-Efficient Heating Systems

Reducing energy consumption is a priority for modern manufacturers. Leshan has integrated advanced heating elements and modular controls into its ODM blow molding machines. These features ensure precise temperature management, reduce waste, and lower operational costs, ultimately contributing to a more sustainable manufacturing process.

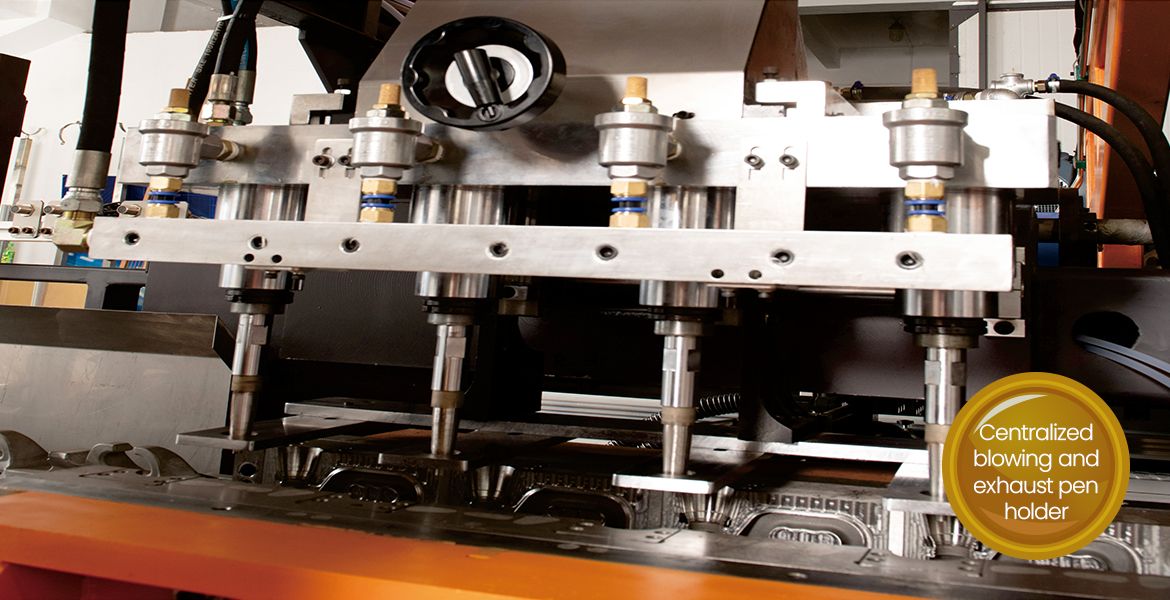

3. High-Speed Automation & Robotics

To maximize productivity, Leshan ODM machines incorporate automated bottle handling, trimming, and quality inspection modules. Robotic automation not only boosts throughput but also ensures consistent product quality by minimizing human error. This is particularly beneficial for businesses aiming to scale-up production while maintaining stringent quality standards.

4. Smart Controls & Digital Integration

Digital transformation is reshaping the manufacturing landscape. Leshan’s latest ODM machines come equipped with intelligent control panels, IoT connectivity, and real-time monitoring systems. These features facilitate predictive maintenance, minimize downtime, and provide actionable data for process optimization.

5. Ergonomic and User-Friendly Designs

Leshan engineers prioritize operator safety and ease of use. Their ODM blow molding machines feature intuitive interfaces, easy-access maintenance points, and compact footprints, enabling seamless integration into existing production lines and improving workplace efficiency.

Case Studies: ODM Success Stories with Leshan

Case Study 1: Pharmaceutical Bottle Production

A leading pharmaceutical packager approached Leshan for a fully automated HDPE bottle blow molding solution with strict contamination controls. Leshan’s ODM team designed a cleanroom-ready machine featuring HEPA filtration, touchless bottle collection, and fully enclosed mold cavities. The result was a machine that exceeded regulatory standards and doubled production capacity.

Case Study 2: Custom Shaped Beverage Bottles

For a beverage startup aiming to disrupt the market with uniquely shaped bottles, Leshan developed a bespoke blow molding machine with interchangeable molds and quick-change tooling. This allowed rapid prototyping and agile production, enabling the company to launch new designs ahead of competitors.

Choosing Leshan: The Strategic Advantage

Partnering with Leshan offers more than just access to advanced machinery— it is a strategic investment in long-term success. Through open collaboration, in-depth consultation, and a relentless drive for improvement, Leshan ensures that each ODM project delivers measurable benefits, from cost savings to expanded market potential.

- Proven track record of innovation and reliability

- Global network for support and service

- Rapid response to evolving customer needs

Design Process: From Concept to Commissioning

Leshan’s ODM journey begins with a thorough needs analysis, followed by solution engineering and iterative prototyping. Clients are engaged at every stage, with transparent project management and milestone reviews. Once the design is finalized, Leshan’s expert technicians oversee machine fabrication, testing, and on-site commissioning, ensuring a smooth transition to full-scale production.

Future Trends in Blow Molding Machine ODM

As the global packaging industry embraces circular economy principles, Leshan’s R&D is focused on further enhancing recyclability and lightweighting of HDPE bottles. The next generation of ODM blow molding machines will emphasize smart manufacturing, AI-driven quality control, and seamless integration with Industry 4.0 ecosystems.

Summary Table: Leshan ODM HDPE Blow Molding Innovations

| Feature | Benefit |

|---|---|

| Multi-Layer Extrusion | Enhanced product protection & branding |

| Energy-Efficient Heating | Reduced costs & eco-friendly operations |

| Automation & Robotics | Higher output & consistent quality |

| Digital Controls | Data-driven production optimization |

| User-Centric Design | Safe and efficient workflows |

FAQs about Leshan’s HDPE Blow Molding Machine ODM Services

What industries benefit most from Leshan’s ODM solutions?

Industries such as beverages, pharmaceuticals, chemicals, cosmetics, and household goods gain significant value from Leshan’s customized HDPE bottle blow molding machines, especially where unique product packaging and high-volume production are crucial.

How long does the ODM process take from concept to delivery?

The duration varies depending on project complexity, but typical timelines range from 3 to 9 months. Leshan’s project management team ensures transparency and timely delivery at every stage.

Can Leshan’s machines be integrated with existing production lines?

Yes, Leshan’s ODM designs prioritize modularity and integration, enabling seamless upgrades or expansions of existing bottle production facilities without major disruptions.

Contact Leshan Today

Whether you are a startup venturing into HDPE bottle manufacturing or an established enterprise seeking to upgrade your production line, Leshan offers the technical expertise and innovative spirit to bring your vision to life. Explore the limitless potential of ODM blow molding machine design and propel your business into the next era of plastic packaging excellence.

Tags:EBM blow molding machine supplier,automatic blow molding machine,full electric blow molding machine supplier,full electric blow molding machine