How Can a Mini Blow Molding Machine Improve Your Production Efficiency

How Can a Mini Blow Molding Machine Improve Your Production Efficiency

Leshan, a leading blow molding machine manufacturer, delivers cutting-edge mini blow molding machines that revolutionize production efficiency for manufacturers in the plastics industry. These compact machines offer significant benefits including a small footprint for optimal space utilization, reduced energy consumption, and rapid setup and changeovers, allowing flexible, agile production. Advanced automation and intelligent process controls minimize manual intervention and errors, ensuring consistent product quality and lower material waste. The modular design allows businesses to scale production capacity according to demand, while user-friendly interfaces and integrated safety systems ease operation and training. Leshan’s mini machines are also Industry 4.0 ready, featuring connectivity for real-time monitoring and maintenance, which maximizes uptime and reduces costly downtimes. Ideal for startups, R&D, or short-run production, these machines offer lower initial investment, reduced utility and labor costs, and enhanced sustainability. Supported by Leshan’s global service network, mini blow molding machines enable manufacturers to respond rapidly to market changes and customer demands, thus driving overall productivity and profitability.

When it comes to maintaining a competitive edge in the plastics manufacturing industry, efficiency is everything. As a prominent blow molding machine manufacturer, Leshan understands the importance of equipping your business with machinery that not only delivers outstanding product quality, but also streamlines operations, reduces costs, and maximizes throughput. Mini blow molding machines are rapidly gaining popularity in production environments seeking agile, scalable, and cost-effective solutions. But how exactly can these compact machines transform your shop floor and drive production efficiency?

undefined

Why Choose Leshan Mini Blow Molding Machines?

At Leshan, we specialize in manufacturing innovative blow molding machines, including mini models designed for versatility and precision. Our mini blow molding machines are engineered with advanced features that cater to small-to-medium batch production or businesses with limited floor space. These machines pack the same punch as their larger counterparts but offer greater flexibility, lower energy consumption, and simplified operations.

Before delving into the specific ways mini blow molding machines can enhance efficiency, it's crucial to understand the unique value proposition Leshan brings to this vital sector of plastics manufacturing.

- Decades of expertise in blow molding technology

- Continuous R&D for innovation-focused solutions

- Commitment to quality, durability, and sustainability

- Tailored after-sales support and training

Key Ways Mini Blow Molding Machines Boost Production Efficiency

1. Space Optimization & Flexible Layouts

Mini blow molding machines from Leshan are specifically designed with a compact footprint. This space-saving design enables manufacturers to maximize available floor area, allowing for more efficient workflow layouts, easy machine integration, and the possibility of running multiple machines in parallel. This flexibility is paramount for startups, pilot plants, or businesses with space constraints.

2. Reduced Energy Consumption

Energy efficiency not only helps reduce operational costs but also supports sustainability initiatives. Leshan mini blow molding machines are built with advanced servo-driven hydraulics and optimized heating systems, ensuring energy is only used where and when necessary. This can result in a substantial reduction in utility expenses and a lower carbon footprint, compared to larger, less efficient systems.

3. Faster Setup and Changeovers

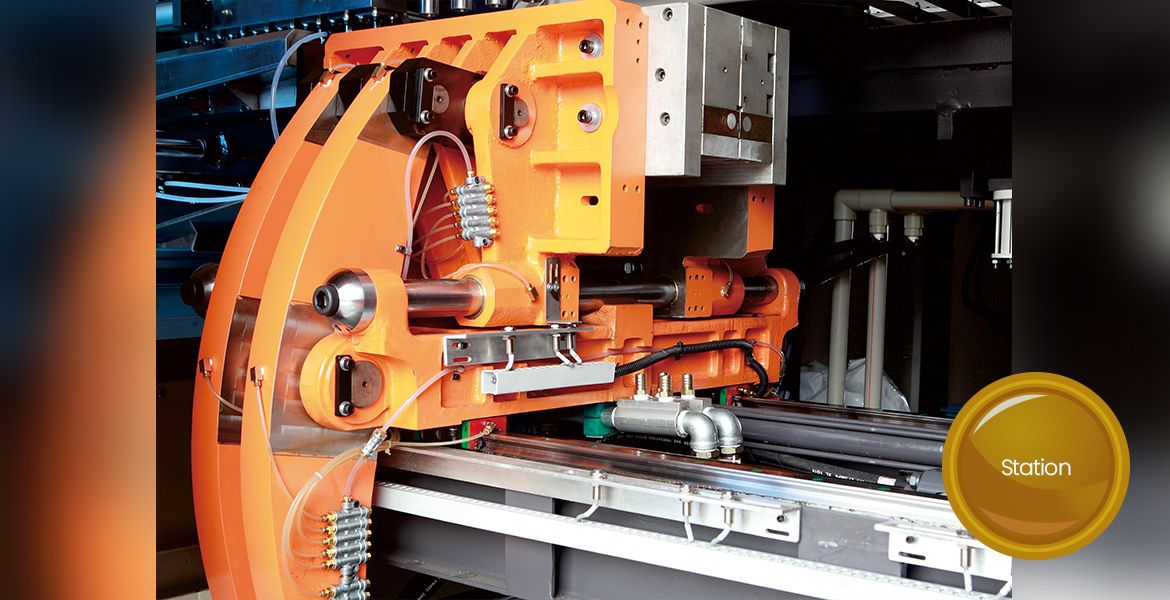

Time is money in manufacturing. Leshan’s mini blow molding machines are engineered for ease of use, with intuitive controls and modular tooling. Quick setup and rapid mold changeovers eliminate lengthy downtimes, enabling operators to switch between product runs with minimal interruption. This adaptability is especially beneficial for producers handling diverse product lines or frequent order changes.

4. Enhanced Automation and Smart Features

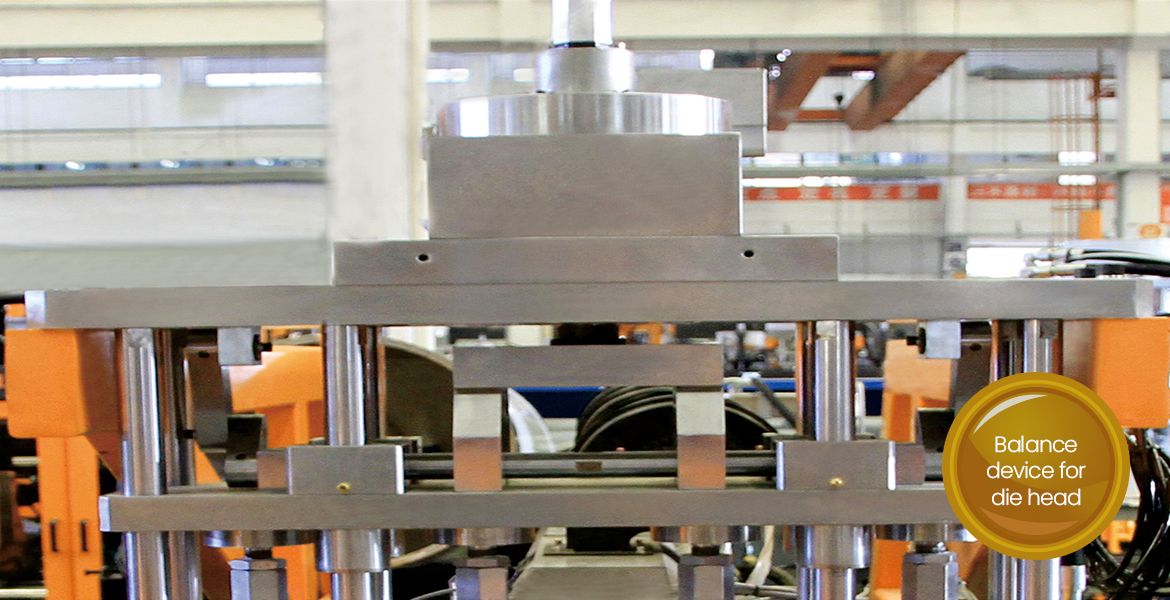

Automation is a key driver of efficiency. Leshan integrates intelligent automation features into mini blow molding machines, such as programmable logic controllers (PLCs), touchscreen HMIs, and remote diagnostics. These features reduce the need for manual intervention, minimize errors, and facilitate predictive maintenance, further streamlining production processes.

5. Superior Quality and Consistency

Production efficiency isn't just about speed; it's also about ensuring product quality and consistency. Leshan’s mini blow molding machines are built to maintain precise control over temperature, pressure, and cycle timing. This results in fewer defects, less material waste, and reduced time spent on quality checks or rework.

Comparing Mini Blow Molding Machines: Leshan’s Distinct Advantages

| Feature | Leshan Mini Blow Molding Machine | Traditional Blow Molding Machine |

|---|---|---|

| Footprint | Compact | Large |

| Energy Consumption | Low | High |

| Setup Time | Minimal | Extensive |

| Automation | Advanced | Limited |

| Changeover Speed | Fast | Slow |

| Maintenance Need | Low | High |

Leshan’s Mini Blow Molding Machine: Real-World Use Cases

Agile Production for Startups

New entrants in the plastics industry often face the dual challenge of restricted capital and limited space. Leshan’s mini blow molding machines provide a solution that allows them to scale their operations gradually, add new products quickly, and maintain consistent quality without major infrastructure investments.

R&D and Prototyping

For companies involved in research, development, or rapid prototyping, Leshan’s mini machines offer a cost-effective platform to test new bottle designs, materials, or manufacturing parameters. Fast changeovers and low material requirements facilitate agile experimentation and innovation cycles.

Short-Run and Custom Production

Personal care, pharmaceuticals, and specialty food industries often require short production runs or customized packaging solutions. Leshan’s compact machines allow for efficient, just-in-time manufacturing without the waste or overhead associated with larger systems.

Cost Savings Through Mini Blow Molding Machines

- Lower Initial Investment: Mini blow molding machines cost significantly less than large-scale variants, making them accessible to a broader range of manufacturers.

- Reduced Utility Bills: Efficient design and energy-saving features translate into lower monthly expenses.

- Decreased Labor Costs: Advanced automation and simple operation reduce the need for a large, specialized workforce.

- Less Material Waste: Consistent output ensures minimal reject rates, optimizing your raw material usage.

Operator-Friendly Design and Safety

Training and safety are critical in any production environment. Leshan’s mini blow molding machines are designed for user-friendly operation. The clear, intuitive controls reduce the learning curve, and in-built safety mechanisms protect both operators and equipment.

Connectivity and Industry 4.0 Readiness

Leshan’s mini blow molding machines are ready for integration with smart manufacturing systems. With connectivity options, remote monitoring, and real-time data analytics, these machines enable you to track performance metrics, schedule maintenance, and optimize production schedules—all from a centralized dashboard.

Scaling Up: Mini Machines as Modular Building Blocks

As your business grows, Leshan’s modular mini blow molding machines can be added incrementally to meet increased demand, without disrupting existing production. This scalability ensures that capacity investments always align with actual business needs, preventing both under- and over-utilization of resources.

Advanced Process Control in Leshan Mini Machines

Precision is a hallmark of Leshan engineering. Our mini blow molding machines offer advanced process control options, including automated monitoring of temperature, air pressure, and mold cooling. This technology not only guarantees product quality but also eliminates production bottlenecks caused by manual errors or process variation.

Environmental Benefits

Compact machines inherently use fewer resources and generate less waste. Coupled with energy-efficient designs, Leshan mini blow molding machines support your company’s sustainability targets. Some models are compatible with bioplastics and recycled materials, further reducing environmental impact.

Enhanced Maintenance and Uptime

Reliability is essential for maintaining high efficiency in a production line. Leshan uses robust components and streamlined design to minimize breakdowns and facilitate quick, easy maintenance. With remote diagnostic capabilities, potential issues can be identified and resolved before they lead to costly downtime.

Unlocking New Market Opportunities

With the agility provided by Leshan mini blow molding machines, manufacturers can quickly respond to market trends, capitalize on niche opportunities, and diversify their product portfolio. This responsiveness is invaluable in today’s fast-paced consumer environments, where customization and rapid delivery are key differentiators.

Trusted Support from Leshan

Leshan doesn’t just supply machines; we partner in your success. Our global network of service professionals offers installation, training, and ongoing support. We help you unlock the full value of your investment and ensure peak efficiency throughout your production lifecycle.

Mini blow molding machines from Leshan represent a smart, forward-thinking investment for manufacturers seeking to boost production efficiency, reduce costs, and accelerate growth. With a focus on technology, reliability, and support, Leshan is your partner for agile, scalable, and sustainable plastics manufacturing.