Stretch Blow Molding Machine Safety Features for Modern Manufacturing

Stretch Blow Molding Machine Safety Features for Modern Manufacturing

Leshan, a leading blow molding machine manufacturer, is recognized for its comprehensive approach to safety in stretch blow molding machines. The company incorporates advanced interlocking systems, emergency stop mechanisms, robust guarding and enclosures, and automated diagnostics to protect operators and ensure compliance with international standards such as CE and ISO. Leshan’s user-friendly interfaces and operator training programs further reduce risks associated with machine operation. Cutting-edge technologies like predictive maintenance, remote monitoring, and smart alarms enhance machine reliability and safety. The company also customizes safety features to fit the unique requirements of industries ranging from food and beverage to pharmaceuticals. Case studies show significant reductions in workplace incidents and downtime with Leshan machines. As safety regulations and technology continue to evolve, Leshan remains committed to continuous improvement, integrating future-ready innovations such as IoT and AI into their safety offerings. Through a combination of engineering excellence, operator education, and responsive support, Leshan sets the standard for safe, efficient, and future-proof blow molding solutions in modern manufacturing.

As manufacturing industries continue to evolve, the safety and efficiency of equipment become more crucial than ever. Leshan, a leading blow molding machine manufacturer, is at the forefront of integrating advanced safety features into stretch blow molding machines. This article explores the key safety features offered by Leshan's machines, addressing the needs and concerns of modern manufacturing environments.

The Importance of Safety in Stretch Blow Molding

Stretch blow molding machines play a vital role in the production of containers for beverages, cosmetics, and pharmaceuticals, among many other industries. Given their speed, complexity, and the potential risks involved, prioritizing safety is essential for safeguarding operators, enhancing productivity, and ensuring compliance with international standards. Leshan is committed to providing blow molding solutions that embody both technological innovation and operator safety.

Leshan’s Approach to Machine Safety

Leshan adopts a multi-faceted approach to safety, combining mechanical design, electronic monitoring, and process automation. These features not only minimize the likelihood of accidents but also help reduce downtime and maintenance costs. Below are some of the main safety elements incorporated into Leshan’s stretch blow molding machines.

1. Advanced Interlocking Systems

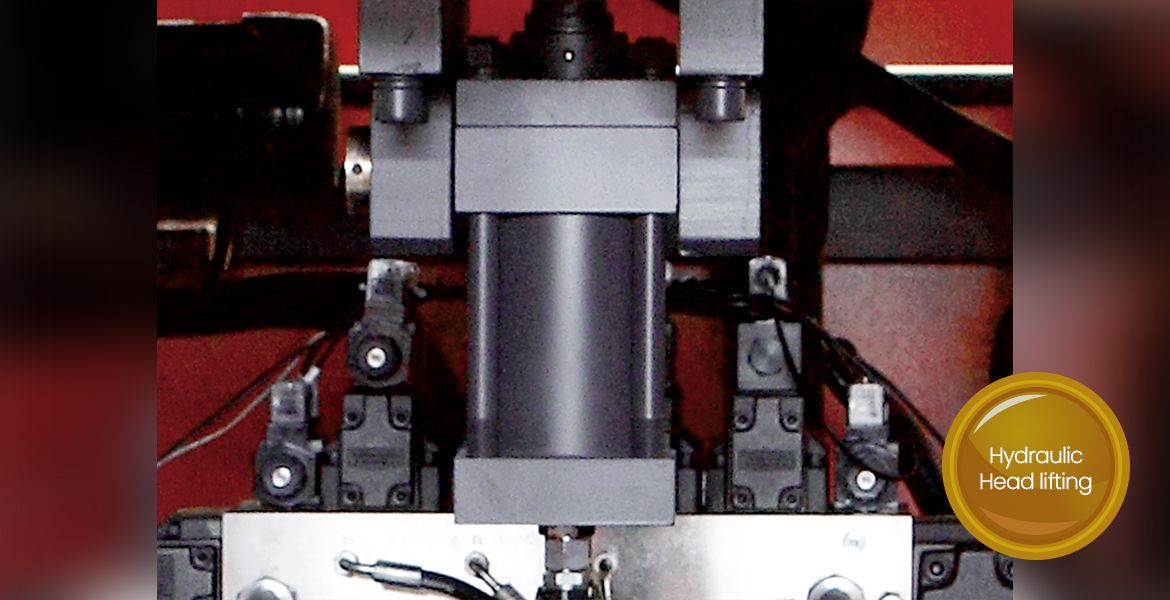

One of the primary safety mechanisms in Leshan's machines is the advanced interlocking system. This ensures that critical machine components, such as the mold opening/closing and preform loading areas, cannot be accessed or operated during hazardous phases of the cycle. The system automatically prevents the machine from starting if access doors or covers are not properly secured.

- Safety switches on all access doors

- Programmable logic controllers (PLCs) for precise monitoring

- Immediate halt of all operations upon unauthorized access

2. Emergency Stop Mechanisms

Every Leshan stretch blow molding machine is equipped with strategically placed emergency stop buttons. These allow operators to instantly shut down the machine in the event of an abnormal situation. Whether dealing with a mechanical jam or an unexpected human error, these emergency stops are designed to be highly visible and easy to activate.

- Multiple emergency stop points across the machine perimeter

- Redundant circuit design for enhanced reliability

- Clearly labelled and illuminated buttons

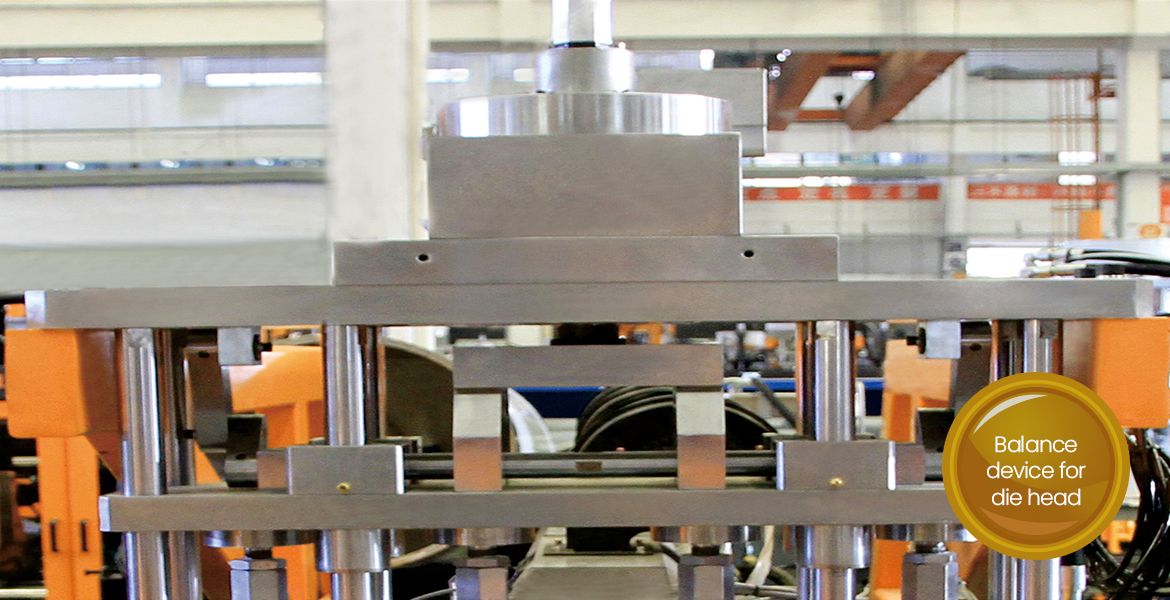

3. Guarding and Enclosures

Leshan prioritizes the use of robust physical guarding and enclosures around moving parts and high-temperature areas. Transparent safety guards allow for visual inspection without exposing operators to risk, while interlocked doors prevent access to dangerous zones during operation.

- Full-length guarding around moving arms and platens

- Heat-resistant shields around heating elements

- Removable yet secure panels for maintenance access

4. Automated Diagnostics and Fault Monitoring

Modern manufacturing demands real-time feedback and immediate response to faults. Leshan's machines incorporate automated diagnostic systems that continuously monitor performance and alert operators to potential issues before they escalate. This includes:

- Integrated sensors to detect abnormal temperatures or pressures

- Automatic shutoff in case of major system faults

- Detailed error codes and troubleshooting guidance via touchscreen HMI

5. Ergonomics and Operator-Friendly Interfaces

The interface between operator and machine is a significant factor in overall safety. Leshan’s blow molding machines feature user-friendly control panels with intuitive navigation, reducing the risk of operator error. Touchscreen HMIs present clear, step-by-step instructions and real-time process data, allowing for rapid decision-making in both routine and emergency situations.

- Easy-to-read displays for critical parameters

- Language customization for global facilities

- Remote monitoring and support capabilities

Compliance with International Safety Standards

Leshan’s stretch blow molding machines are designed to meet or exceed global safety standards, including CE, ISO, and other industry-specific certifications. Compliance is maintained through rigorous testing, regular audits, and continuous improvement of both hardware and software components.

| Standard | Description |

|---|---|

| CE | European safety, health, and environmental protection |

| ISO | International Organization for Standardization guidelines |

| Local Regulations | Country and region-specific safety norms |

Operator Training and Safety Protocols

Leshan recognizes that even the most advanced safety features require proper operator understanding and training. To this end, the company offers comprehensive training programs, detailed operation manuals, and on-site technical support. These initiatives ensure all personnel are familiar with machine functions, emergency procedures, and best safety practices.

- Hands-on training sessions for operators and maintenance staff

- Regular safety audits and refresher courses

- Customized training modules for specific factory needs

Innovative Technologies Enhancing Safety

Leshan continues to invest in research and development, resulting in ever-improving safety features for their blow molding machines. Some of the most promising technologies include:

- Predictive Maintenance Algorithms: Leveraging machine data to forecast and prevent failures before they occur

- Remote Monitoring: Enabling technicians to supervise safety status and intervene remotely if required

- Energy-Efficient Safety Systems: Integrating low-power sensors and actuators to ensure safety without excessive energy consumption

- Smart Alarms: Advanced audio-visual alarms with contextual information to guide operator response

- Automatic Lockout/Tagout Procedures: Digital systems that enforce safe shutdown for maintenance

Customization for Diverse Manufacturing Environments

No two manufacturing operations are the same. Leshan offers customization options to tailor safety features to the specific needs of each client. Whether operating in the food and beverage sector, pharmaceuticals, or industrial packaging, Leshan’s engineering team collaborates with customers to implement appropriate safety systems, ensuring seamless integration with facility protocols.

- Industry-specific guarding (e.g., splash-proof for beverage production)

- Enhanced cleanroom compatibility for pharmaceuticals

- Upgradable safety modules to future-proof investment

Maintenance and Continuous Improvement

Safety does not end with machine delivery. Leshan emphasizes proactive maintenance and continuous improvement, encouraging customers to schedule preventive service checks and software updates. This approach ensures all safety features remain operational and up-to-date with the latest standards and technologies.

- Scheduled safety inspections and testing

- Remote diagnostics and troubleshooting support

- Customer feedback loops for ongoing product development

Case Studies: Leshan Safety in Action

Leshan’s safety-centric approach has been validated across diverse industries. In high-throughput beverage plants, advanced interlocks and predictive maintenance have reduced incident rates by over 30%. In pharmaceutical environments, customized cleanroom-compatible guarding ensures both product purity and operator protection. Across all sectors, Leshan's commitment to safety has translated into higher uptime, reduced insurance costs, and greater workforce satisfaction.

- Beverage manufacturer: Zero recordable injuries over three years with Leshan machines

- Pharmaceutical client: Passed all local and international safety audits on first inspection

- Industrial packaging operation: Reduced downtime linked to safety incidents by 40%

Future Trends: Smart Safety Integration

Looking ahead, Leshan is preparing for the next wave of safety innovations. The integration of Internet of Things (IoT) devices, AI-driven hazard detection, and adaptive machine learning systems will further elevate operator safety. These advancements promise not only safer workplaces but also more flexible and responsive manufacturing operations.

- Wearable safety devices for real-time operator health monitoring

- Automated safety compliance documentation and reporting

- Collaborative robots (cobots) with built-in safety intelligence

Why Choose Leshan for Blow Molding Machine Safety?

With a legacy of innovation and a global reputation for reliability, Leshan stands as a preferred partner for manufacturers investing in stretch blow molding technology. The company’s relentless focus on safety—supported by advanced engineering, rigorous testing, and customer-oriented customization—ensures that every Leshan machine delivers peace of mind alongside world-class performance.

- Comprehensive safety feature set

- Proven track record in diverse industries

- Unmatched support and training infrastructure

Leshan's stretch blow molding machines are more than production tools—they are vital components in building a safe, efficient, and competitive manufacturing operation in the modern era.