Why Is Customization Essential for HDPE Bottle Blow Molding Machine OEM Solutions

Why Is Customization Essential for HDPE Bottle Blow Molding Machine OEM Solutions

Customization is crucial for OEMs sourcing HDPE bottle blow molding machines, as the packaging industry faces rapidly evolving demands for diverse bottle designs, stringent quality standards, regulatory compliance, and sustainability. Leshan, a leading blow molding machine manufacturer, specializes in delivering highly customized solutions that empower OEMs to address unique product requirements and production challenges. Through consultative solution development, innovative machine design, and ongoing technical support, Leshan ensures that each machine aligns precisely with the OEM’s needs—whether that involves unique shapes, advanced material capabilities, or specific automation features. Customization boosts efficiency, reduces cost, maintains quality, and enables rapid adaptation to market changes. By partnering with Leshan, OEMs gain the flexibility to launch new products faster, optimize production, and stay ahead in a competitive, ever-changing marketplace.

In the dynamic world of packaging, adaptability is critical to success. Leshan, a renowned blow molding machine manufacturer, understands that the journey toward excellence in HDPE bottle production is paved with a deep commitment to customization. For OEMs (Original Equipment Manufacturers) in the HDPE bottle industry, the need for tailored blow molding machine solutions is more pronounced than ever. This article delves into the essential role that customization plays in the development and implementation of HDPE bottle blow molding machine OEM solutions, with a special focus on Leshan’s expertise and innovations.

The Growing Complexity of the HDPE Bottle Market

The global HDPE bottle market has witnessed exponential growth due to its versatility, durability, and recyclability. However, with this growth comes increasing complexity. Today’s markets demand bottles in a myriad of shapes, sizes, and functionalities. Consumer preferences, branding needs, legislative changes, and sustainability goals all drive a need for flexible manufacturing technologies. Leshan, as a leading blow molding machine manufacturer, recognizes that a one-size-fits-all approach is inadequate for coping with such diversity.

Rising Demands from OEMs

- Diverse shapes and capacities: From compact sample vials to large-volume containers, OEMs must cater to unique application needs.

- Stringent quality standards: Uniform wall thickness, perfect transparency, and consistent weights are non-negotiable.

- Regulatory compliance: Packaging for food, pharmaceuticals, and chemicals must adhere to specific standards, often requiring specialized production capabilities.

- Faster product cycles: Market trends change rapidly, requiring agile manufacturing solutions.

- Sustainability: Lightweighting, recyclability, and the use of biodegradable additives are increasingly important.

Customization: A Strategic Imperative

Customization is no longer a luxury—it's a strategic imperative. Leshan’s expertise in blow molding machine manufacturing empowers OEMs to address unique challenges and capitalize on new opportunities. Here’s why:

Precision Engineering for Unique Applications

Each OEM may require bottles with distinct neck finishes, handle positions, or intricate designs. Leshan’s blow molding machine offerings are designed for flexibility, allowing for extensive mold customization. This ensures consistency in output and meets specific branding or functionality goals.

Maximizing Production Efficiency

Customized solutions allow OEMs to optimize cycle times, minimize material waste, and reduce energy consumption. By tailoring the blow molding process to the unique characteristics of HDPE and specific bottle requirements, Leshan helps manufacturers achieve higher throughput without sacrificing quality.

Adapting to Different Production Scales

Whether an OEM operates a single production line or a large-scale facility, Leshan’s blow molding machines can be customized to match the desired output volume. Modularity and scalability in machine design enable seamless expansion and quick adaptation to market changes.

The Leshan Approach to HDPE Bottle Blow Molding Customization

Leshan has established itself as a blow molding machine manufacturer that places customer needs at the core of its operations. The company’s approach to customization involves in-depth consultations, technological innovation, and rigorous testing. Let’s break down the process:

Consultative Solution Development

The journey starts with understanding the OEM’s exact requirements—from bottle design and material specifications to production targets and regulatory constraints. Leshan’s experts work closely with clients to develop a holistic solution that balances performance, cost, and sustainability.

Innovative Machine Design

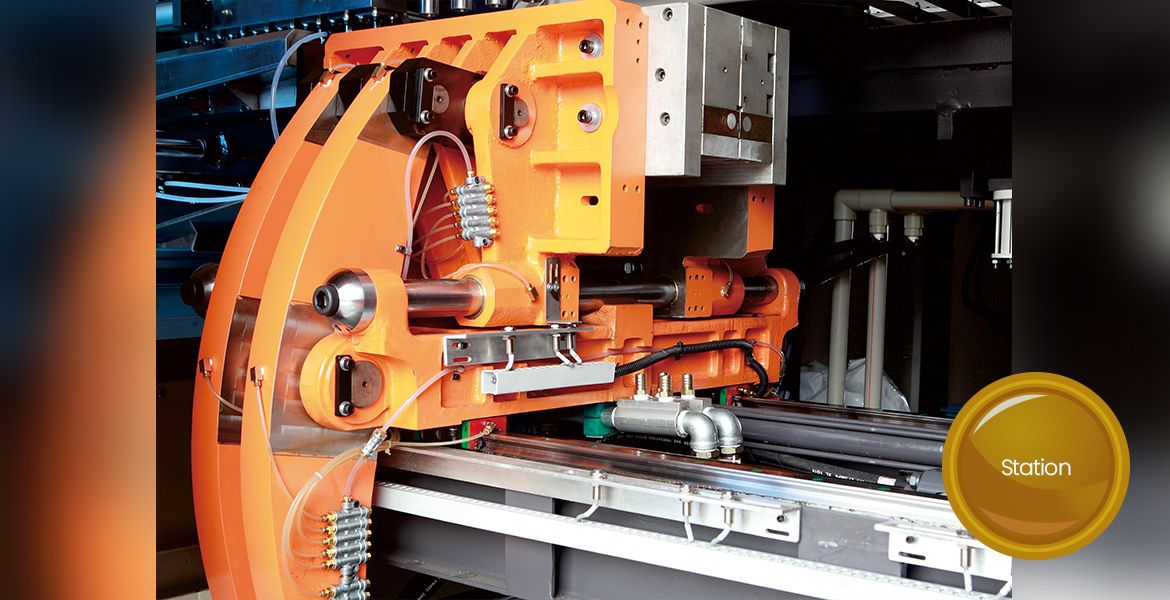

- Flexible Clamping Units: Accommodate a broad range of bottle sizes and shapes.

- Advanced Extrusion Heads: Support multi-layer, multi-color, and barrier bottle production.

- Automated Control Systems: Enable quick recipe changes and real-time quality monitoring.

- Integrated Post-processing: In-mold labeling, handle welding, and leak testing can be incorporated seamlessly.

Material Compatibility and Process Optimization

HDPE as a material presents unique processing challenges—its melt viscosity, cooling behavior, and shrinkage rates all impact final product quality. Leshan’s machines are engineered for precise control of temperature, pressure, and extrusion speed, ensuring superior bottle clarity and integrity. Customization extends to screw design, die geometry, and cooling systems, maximizing yield and minimizing defects.

Quality Assurance and Long-Term Support

Customization doesn’t end at machine delivery. Leshan provides ongoing technical support, training, and preventive maintenance programs. Continuous improvement loops based on real-world feedback help OEMs achieve operational excellence and adapt to evolving market trends.

Case Studies: Real-World Impact of Customization

Pharmaceutical Bottles: Safety and Accuracy

A prominent pharmaceutical OEM approached Leshan with a need for tamper-evident, multi-layer HDPE bottles. Custom blow molding machines were engineered with specialized neck-cutter assemblies, precise temperature controls, and integrated leak testers. The result: reduced contamination risk, consistent dosing accuracy, and regulatory compliance.

Dairy Packaging: Lightweight and Robust

Another client needed lightweight bottles for dairy products that could withstand the rigors of cold-chain logistics. Leshan’s customization enabled optimized wall thickness distribution and handle integration, delivering a bottle that was both robust and cost-effective.

Household Chemical Containers: Complex Geometries

A manufacturer of household cleaners wanted bottles with ergonomic grips and child-safety closures. Leshan responded by customizing the blow molding machine’s clamping and extrusion systems to handle complex geometries, resulting in enhanced consumer safety and brand differentiation.

Benefits of Customization: The Leshan Advantage

- Shorter time-to-market: Rapid prototyping and mold adjustments accelerate product launches.

- Reduced production costs: Precision engineering minimizes material waste and energy usage.

- Improved quality and consistency: Custom controls ensure every bottle meets rigorous standards.

- Future-proofing investment: Modular designs enable easy upgrades and adaptation to new bottle types or regulations.

- Comprehensive support: From design to after-sales service, Leshan partners with OEMs at every step.

Customization Trends Shaping the Future of Blow Molding

Several industry trends are reinforcing the importance of customization for OEMs and their blow molding machine suppliers:

- Digital Integration: Industry 4.0 technologies for machine monitoring, predictive maintenance, and data-driven process optimization are enhancing flexibility and reliability.

- Sustainability Initiatives: Increasing adoption of recycled HDPE, biodegradable additives, and energy-saving features.

- Smart Automation: Robotics and AI-driven quality control are reducing labor dependence and improving consistency.

- Globalization: OEMs require machines that can adapt quickly to diverse regulatory environments and supply chain dynamics.

Leshan’s Customization Toolkit

- Proprietary software: For recipe management and process analytics.

- Customizable hardware modules: Interchangeable extrusion heads, clamps, and cooling assemblies.

- Collaborative design process: Involving end-users, mold-makers, and automation partners.

- Pilot testing: Full-scale prototyping before commercial roll-out.

Challenges and Opportunities

While customization delivers clear benefits, it does present certain challenges. Increased complexity can lead to longer lead times and higher upfront costs. However, Leshan’s streamlined project management and modular platform reduce these risks. The opportunities far outweigh the challenges, as customized equipment enables OEMs to respond faster to market shifts and unlock new product categories.

Why Leshan Is the Trusted Partner for OEM Customization

Leshan’s legacy as a blow molding machine manufacturer is built on a foundation of technical mastery, customer-centric innovation, and long-term partnership. The company’s dedication to customization ensures that OEMs are never forced to compromise on performance, flexibility, or quality. By choosing a partner like Leshan, manufacturers can future-proof their operations and thrive in today’s competitive HDPE packaging landscape.

Tags:EBM blow molding machine application,full electric blow molding machine,HDPE bottle blow molding machine application,automatic blow molding machine supplier