Why Is Maintenance Crucial for Container Blow Molding Machine Longevity

Why Is Maintenance Crucial for Container Blow Molding Machine Longevity

Maintenance is the cornerstone of longevity and performance for container blow molding machines. Leshan, as a premier blow molding machine manufacturer, illustrates how diligent maintenance routines—spanning daily lubrication, scheduled inspections, cleaning, timely parts replacement, and calibration—can prevent unexpected breakdowns, improve product quality, and maximize operational lifespan. Properly maintained machines reduce costly downtime, minimize operating costs, and ensure consistent, defect-free production. Leshan supports operators with tailored maintenance guides, training, spare parts management, and smart diagnostics, ensuring every client gets the most from their investment. Emphasizing preventive and predictive maintenance, Leshan not only safeguards machine value but also drives continuous client success in a competitive industry.

As a trusted blow molding machine manufacturer, Leshan has continually emphasized the critical role that maintenance plays in extending the lifespan and performance of container blow molding machines. Maintenance, when properly scheduled and executed, not only ensures optimal productivity but also minimizes costly downtimes, enhances safety, and preserves the quality of the blow-molded products. In this article, we delve into the foundations of why maintenance is so vital, practical steps for blow molding machine upkeep, and how Leshan’s expert support can help operators achieve the highest levels of equipment reliability.

Understanding Container Blow Molding Machine Operations

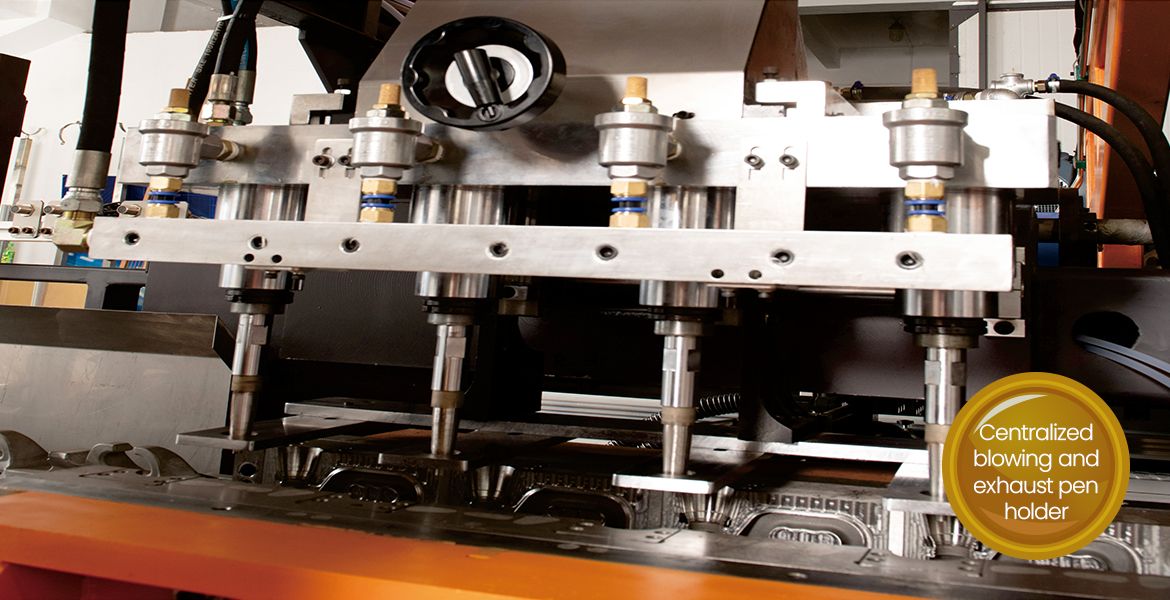

Container blow molding machines are engineered to manufacture hollow plastic parts by inflating heated plastic into a mold cavity. The process relies on several integrated components, including extrusion systems, molds, hydraulic units, pneumatics, and electronic controls. Any disruption or degradation in these components can directly affect product consistency and cycle times.

undefined

tornado full electric ebm machine

plastic blow molding machine

hdpe hydraulic plastic blow molding machine

full electric ebm machine

all electric blow molding machines

high power ebm complete machine

The Intricacies of Blow Molding Machine Mechanics

- Extrusion System: Responsible for melting and shaping the polymer prior to molding.

- Mold Clamping and Forming: Ensures the mold is tightly sealed and the container is shaped accurately.

- Hydraulics and Pneumatics: Power the movement of machine parts and the inflation process.

- Electronic Controls: Govern the operation through precise timing and parameters.

Regular usage causes normal wear in each of these areas. Without systematic attention, minor issues can escalate, affecting not only productivity but also the operational life of the entire machine.

Why Maintenance Is Essential for Longevity

For manufacturers such as Leshan, whose reputation depends on delivering superior blow molding machines, highlighting the importance of maintenance is a core value. The reasons are multifaceted, extending from operational efficiency to financial savings and quality assurance.

1. Preventing Unexpected Breakdowns

Unplanned downtime is one of the most expensive setbacks for any manufacturing line. Frequent checks and proactive replacements of worn parts help in identifying signs of imminent failure before they halt production. Routine inspections can reveal issues in hydraulic seals, heating elements, and sensors, making them easier and less costly to fix.

2. Maximizing Equipment Lifespan

Consistent maintenance slows the natural aging process of machine parts. Lubrication of moving parts reduces friction, proper alignment prevents structural deformities, and regular cleaning removes contaminants that could cause corrosion or blockages. Leshan’s machines are designed for durability, but even the best equipment needs attentive care to reach its maximum potential lifespan.

3. Ensuring Product Quality and Consistency

Container blow molding relies on uniform heating, precise mold closure, and controlled air pressure. Contaminants or degraded components can cause inconsistencies in wall thickness, deformities, and product rejection. By following a scheduled maintenance program, operators ensure every container meets the stringent quality standards that customers expect from Leshan blow molding machines.

Key Maintenance Tasks for Blow Molding Machines

| Maintenance Task | Description | Frequency |

|---|---|---|

| Lubrication | Apply recommended lubricants to moving parts to reduce wear. | Daily/Weekly |

| Inspection | Visual and functional checks of critical systems (hydraulics, pneumatics, electrical). | Weekly/Monthly |

| Cleaning | Remove dust, debris, and product residues from accessible surfaces. | Daily/Weekly |

| Parts Replacement | Change out worn-out seals, filters, and heaters as required. | As needed/Per schedule |

| Calibration | Verify and adjust control systems for accurate operation. | Quarterly/Annually |

Leshan provides machine-specific maintenance guides, ensuring that every operator knows what tasks are necessary and when. This systematic approach reduces the risk of human error and helps in tracking historical data for predictive maintenance strategies.

Benefits of a Diligent Maintenance Program

- Increased Machine Uptime: Regular checks reduce the likelihood of unplanned outages.

- Reduced Overall Operating Costs: Preventing major repairs saves both time and money.

- Improved Product Consistency: Well-maintained machines produce higher and more uniform product quality.

- Enhanced Safety: Maintenance ensures that all safety features function correctly, reducing the risk of workplace accidents.

- Long-Term Asset Value: Maintained machines retain more value and can be resold or upgraded with ease.

These advantages are magnified in high-volume production environments, where every minute of downtime can mean substantial financial loss. Leshan’s emphasis on preventive and predictive maintenance is key to helping clients reach these goals.

Common Maintenance Challenges and Solutions

Operator Training

One of the most significant challenges is ensuring that all staff are sufficiently trained in both routine and advanced maintenance procedures. Leshan offers comprehensive training programs and support resources to empower operators with the knowledge necessary to keep machines running smoothly.

Spare Parts Management

Stocking the right spare parts is vital for minimizing downtime. Leshan assists customers by providing part lists and quick delivery options, ensuring that essential components are always available on-site.

Documentation and Scheduling

Effective maintenance requires detailed records of past interventions and a clear schedule for future tasks. Leshan’s proprietary maintenance management solutions make it easy to track every action, plan ahead, and receive timely reminders.

Leshan’s Approach to Maintenance Support

At Leshan, after-sales service is not an afterthought but an integral component of the customer experience. From the moment a container blow molding machine is commissioned, Leshan’s technical support team provides ongoing guidance, remote diagnostics, and, when necessary, on-site assistance. This partnership approach ensures that even complex maintenance is handled efficiently and that clients enjoy the full benefits of their investment.

Best Practices from Leshan for Maximum Machine Longevity

- Establish a strict daily, weekly, and monthly maintenance routine.

- Document every maintenance action and track machine performance over time.

- Invest in operator training, with periodic refresher courses.

- Use only genuine Leshan replacement parts and recommended lubricants.

- Engage with Leshan’s service team for audits and expert advice.

By adopting these strategies, operators can not only prevent common issues but also optimize machine settings for maximum throughput and lowest defect rates.

Case Study: Leshan’s Success Stories

Several global brands have benefited from Leshan’s commitment to maintenance excellence. One leading beverage manufacturer reported a 30% increase in annual production output after adopting the Leshan-recommended maintenance schedule, with a simultaneous decrease in machine-related defects. Another packaging company extended the operational life of their oldest blow molding line by over five years, thanks to regular audits and timely upgrades suggested by Leshan’s engineers.

Future Trends in Blow Molding Machine Maintenance

Predictive maintenance powered by IoT sensors and AI analytics is revolutionizing the way blow molding machines are serviced. Leshan is at the forefront of integrating smart diagnostics, enabling operators to receive real-time alerts on wear patterns, temperature anomalies, and lubrication status. These innovations further reduce downtime and enable even greater longevity for container blow molding machines.

Why Trust Leshan as Your Blow Molding Machine Manufacturer?

Leshan’s decades-long experience, commitment to innovation, and customer-centric maintenance philosophy set it apart in the blow molding industry. Every Leshan machine is built with serviceability in mind and supported by a responsive, knowledgeable team dedicated to client success. From initial setup to ongoing maintenance, Leshan stands by its promise: maximum uptime, outstanding product quality, and industry-leading machine life.