How Can Automatic Blow Molding Machine OEM Solutions Enhance Your Production Efficiency

How Can Automatic Blow Molding Machine OEM Solutions Enhance Your Production Efficiency

Leshan, a prominent blow molding machine manufacturer, offers advanced automatic blow molding machine OEM solutions designed to optimize production efficiency for manufacturers of plastic containers and hollow products. These solutions encompass high-speed, energy-efficient machinery equipped with precision controls and modular customization options, enabling businesses to tailor systems to specific production needs. By integrating automation features such as robotics, smart sensors, and IoT connectivity, Leshan enhances workflow by automating routine tasks, minimizing downtime, and boosting throughput.

OEM solutions from Leshan also focus on reducing operational costs by improving energy efficiency, lowering maintenance requirements, and minimizing labor dependency. The incorporation of data-driven management tools enables real-time monitoring of key production metrics, supporting swift decision-making and continuous improvement initiatives.

Furthermore, Leshan’s machines support superior product quality and consistency through automated quality control systems and precise process management, reducing waste and rework. The modular and flexible design of their OEM solutions ensures companies can scale, adapt to new challenges, and remain competitive as market demands evolve. Comprehensive training and after-sales support round out Leshan’s approach, ensuring clients maximize the benefits of their investment.

In summary, Leshan’s automatic blow molding machine OEM solutions empower manufacturers to achieve higher productivity, better quality, and long-term cost savings, positioning them for success in a rapidly changing industry.

In the dynamic landscape of modern manufacturing, efficiency is the keystone that allows businesses to thrive and remain competitive. For industries involved in producing plastic containers, bottles, and other hollow products, the role of blow molding machines is indispensable. Leshan, a renowned blow molding machine manufacturer, understands the intricacies of these production lines and provides advanced automatic blow molding machine OEM solutions designed to elevate operational efficiency.

The Evolution of Blow Molding Technology

Blow molding has evolved significantly over the past decades, transforming from manual labor-intensive processes to automated, high-precision systems. Today, automatic blow molding machines are at the forefront of this technological revolution. Leshan’s commitment to innovation brings forth OEM solutions that blend cutting-edge technology with practical manufacturing needs, ensuring that productivity is optimized at every stage.

What Sets Leshan Automatic Blow Molding Machines Apart?

Leshan’s automatic blow molding machines are crafted for flexibility, reliability, and scalability. By incorporating customizable OEM solutions, businesses can tailor machines to specific requirements, be it for unique product shapes, different resin types, or varying production capacities. This adaptability is crucial for companies seeking to enhance their efficiency without compromising on quality or consistency.

- High-Speed Operation: Leshan machines are engineered for rapid cycle times, reducing downtime and maximizing throughput.

- Precision Controls: Advanced PLC and HMI control systems allow for accurate process management, minimizing errors and material wastage.

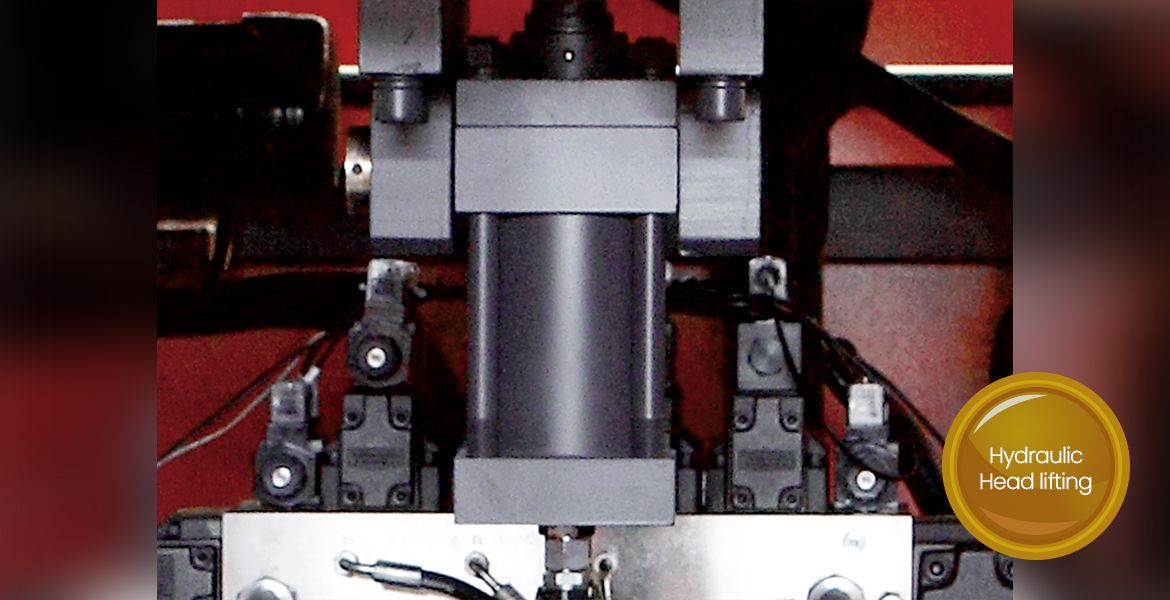

- Energy Efficiency: Features such as servo-driven hydraulic systems and optimized thermal management lead to lower energy consumption.

- Low Maintenance Design: Robust construction and intelligent design reduce the frequency and cost of maintenance interventions.

- Modular OEM Solutions: Tailored modules enable easy upgrades, future-proofing your investment and adapting to changing market demands.

OEM Solutions: Customization for Maximum Efficiency

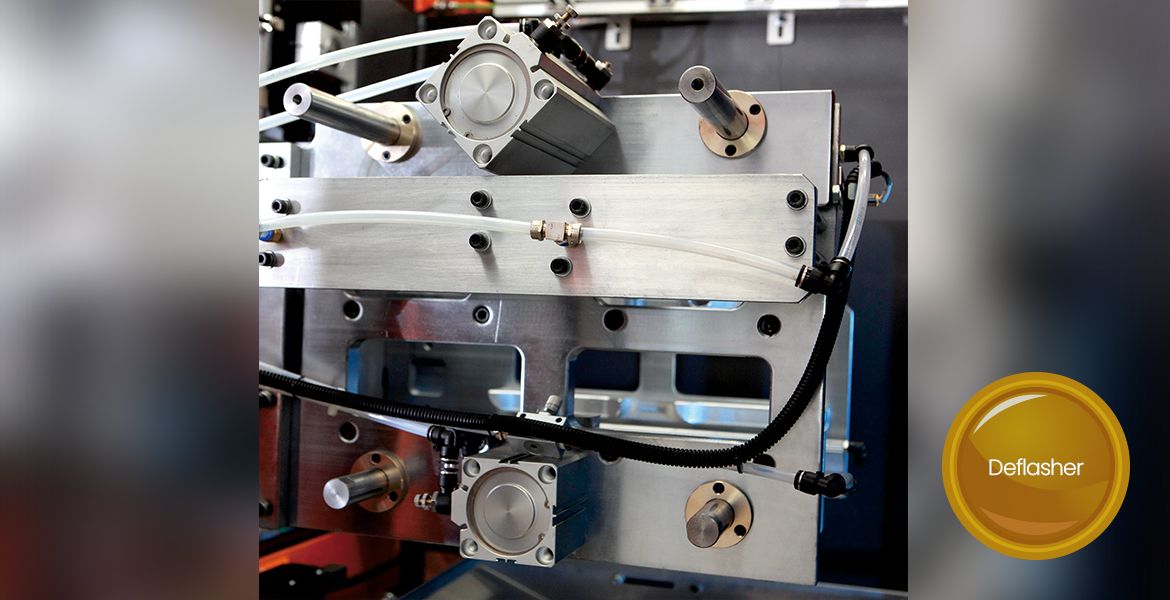

OEM solutions from Leshan are not mere add-ons; they represent a holistic approach to equipment customization. By working closely with clients, Leshan develops blow molding machines that seamlessly integrate with existing production lines, optimizing layout and workflow. Customization extends to mold design, control interfaces, automation levels, and even auxiliary equipment such as robots or vision inspection systems.

Benefits of Tailored OEM Blow Molding Machines

| Benefit | Impact |

|---|---|

| Reduced Cycle Time | Faster production speeds result in higher output and quicker turnaround. |

| Material Savings | Advanced process controls reduce waste and ensure uniform product weight/thickness. |

| Quality Consistency | Automated systems maintain stable parameters, minimizing human error and quality fluctuations. |

| Scalability | Modular design allows capacity upgrades without major downtime. |

| Integration | OEM solutions facilitate seamless connectivity with ERP and MES systems for real-time data management. |

Streamlining Production Workflow with Automation

Automation is no longer a luxury; it is a necessity for manufacturers aiming for excellence. Leshan’s automatic blow molding machines leverage robotics, IoT connectivity, and smart sensors to automate routine tasks. This includes automated preform loading, mold changes, product ejection, and quality inspection. By eliminating bottlenecks, Leshan helps manufacturers achieve uninterrupted production and enhanced overall equipment effectiveness (OEE).

Key Automation Features in Leshan Blow Molding Machines

- Smart Material Handling: Automated conveyors and feeders synchronize with machine cycles for smooth material flow.

- Integrated Quality Control: High-resolution cameras and sensors detect defects instantly, ensuring only flawless products reach packaging.

- Remote Monitoring: IoT-enabled machines provide live status updates and predictive maintenance alerts.

- Flexible Programming: Operators can program complex product cycles and recipes, adapting quickly to changing orders.

Reducing Operational Costs

Production efficiency is directly linked to cost management. Leshan’s automatic blow molding machine OEM solutions are designed to reduce operational expenses across multiple dimensions. Energy-efficient drives, optimized heating systems, and low-maintenance components collectively lower utility and repair costs. Additionally, automation reduces labor dependency, allowing skilled personnel to focus on higher-value activities such as process optimization and innovation.

Case studies from Leshan reveal up to 30% reductions in energy consumption and a marked decline in maintenance-related downtime among clients who have adopted their OEM systems. These savings translate directly into improved profit margins and greater competitive agility.

Data-Driven Production Management

In today’s digital manufacturing era, data is the backbone of strategic decision-making. Leshan integrates advanced data capture and reporting functions into its blow molding machines, enabling manufacturers to monitor KPIs such as cycle times, reject rates, and energy usage. This real-time insight supports continuous improvement initiatives and rapid response to issues, further enhancing production efficiency.

Enhancing Product Quality and Consistency

Efficiency is not just about speed—it’s about doing things right, every time. Leshan automatic blow molding machine OEM solutions utilize sophisticated temperature and pressure controls, precision mold alignment, and real-time monitoring to ensure that each product meets stringent quality standards. Automated inspection and ejection systems remove non-conforming items, minimizing the risk of downstream defects and customer complaints.

- Stable Process Parameters: Maintain ideal settings for temperature, pressure, and cooling cycles.

- Automated Defect Detection: Instant identification and removal of defective products.

- Consistent Wall Thickness: Ultrasonic or laser measurement systems guarantee uniformity.

- Traceability: Each product is tracked from raw material to finished item, aiding in quality audits and recalls.

Supporting Innovation and New Product Development

Leshan’s OEM approach is highly collaborative, supporting customers in launching new products with challenging specifications. By designing blow molding machines that can handle novel polymer blends, intricate shapes, or multi-layer constructions, Leshan enables manufacturers to react quickly to market trends and consumer demands. This agility is a critical component of long-term efficiency.

Flexibility and Future-Proofing Your Investment

The manufacturing landscape is in constant flux, with new regulations, materials, and product designs emerging frequently. Leshan’s customizable OEM blow molding solutions are built with flexibility in mind. Modular components, software upgrades, and scalable configurations ensure that your investment remains relevant and capable of meeting future challenges without the need for complete system overhauls.

Advantages of Modular OEM Design

- Quick Mold Changeover: Switch between product lines with minimal downtime.

- Easy Integration: Add or upgrade automation modules as needed.

- Expandable Capacity: Increase output by adding more cavities or parallel machines.

- Software Updates: Stay up-to-date with process optimization and compliance standards.

Training and After-Sales Support

Efficiency gains from automation are maximized when operators and technicians are well-trained. Leshan provides comprehensive training programs and ongoing support for its OEM blow molding machines. From initial commissioning to routine maintenance and process optimization, Leshan’s team ensures that clients can operate their systems at peak performance levels.

Remote diagnostics and virtual support channels further enhance uptime, allowing for quick troubleshooting and issue resolution without prolonged interruptions.

Leshan: Your Partner for Efficient Blow Molding Production

As a leading blow molding machine manufacturer, Leshan is dedicated to helping businesses unlock their full production potential. By delivering automatic blow molding machine OEM solutions tailored to specific needs, Leshan empowers manufacturers to achieve cost-effective, high-quality, and flexible production.

Key Takeaways on Efficiency Enhancement

- Customizable OEM solutions align with unique production requirements.

- Automation streamlines workflow and reduces human error.

- Data-driven management supports continuous improvement.

- Energy-efficient design and low maintenance minimize costs.

- Modular flexibility ensures future readiness for evolving market demands.